2025-07-17 東京科学大学

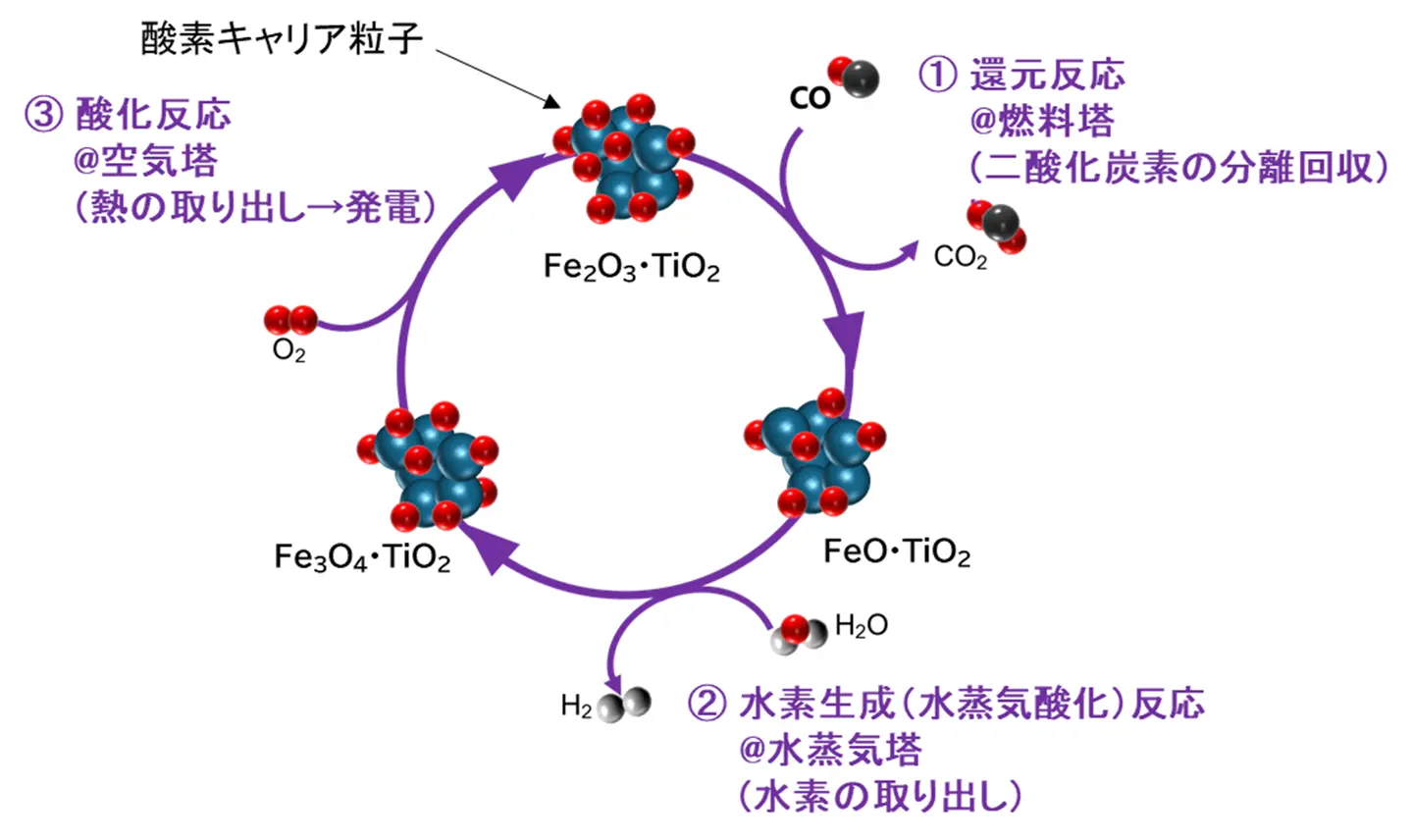

図1. 3塔型ケミカルルーピング反応(還元反応、水蒸気酸化反応、完全酸化反応)

<関連情報>

- https://www.isct.ac.jp/ja/news/d2blhhp81h2w

- https://www.isct.ac.jp/plugins/cms/component_download_file.php?type=2&pageId=&contentsId=1&contentsDataId=1944&prevId=&key=a6d4aa1ad8616763359743d5b11b0419.pdf

- https://www.sciencedirect.com/science/article/abs/pii/S030626192501092X

ケミカルルーピングにおける反応性と水素収率を改善するカリウムおよびカルシウム修飾イルメナイト Potassium and calcium-modified ilmenites for improved reactivity and hydrogen yield in chemical looping

Zhuang Sun, Junichiro Otomo

Applied Energy Available online: 4 July 2025

DOI:https://doi.org/10.1016/j.apenergy.2025.126362

Highlights

- K and Ca modified ilmenites as low-cost carriers were proposed;

- K promotes the homogeneous dispersion of Ca and formation of CaTi1-xFexO3-δ;

- The redox kinetics was improved compared to pure ilmenite;

- The H2 yield and lattice oxygen utilization rate were improved than pure ilmenite.

Abstract

Ilmenite is a promising oxygen carrier for scaling up chemical looping hydrogen production processes but shows limited redox kinetics and thus low H2 yield. On-site modification of ilmenite with alkali and alkaline earth metals (AAEM) offers a cost-effective way to reduce costs and streamline procedures since these metals could be naturally derived from feedstock such as biomass. In this study, calcium and potassium were used to modify ilmenite, the Ca- and/or K-modified ilmenites were prepared, characterized, and comprehensively studied in terms of reactivity and H₂ yield with a fluidized bed reactor. The Kunii-Levenspiel model was applied to analyze the reaction insights and predict upscaled reaction design. The formation of new phases of K-Ti-Fe and Ca-Ti-Fe oxides and their distribution led to elevated performances for the modified ilmenites. Ilmenite co-modified with Ca and K (5wt.%K2O30wt.%CaO-IL, 5K30Ca-IL) showed the best kinetics and highest H₂ yield, followed by K-only and then Ca-only modified ilmenite. At 900 °C, 5K30Ca-IL demonstrated a maximum improvement of 60 % in the steam oxidation rate constant, a reduction in CO consumption of up to 57 %, and a maximum enhancement in H₂ yield of ∼440 %, and up to ∼5.5 times higher energy efficiency. The reactor size for 5K30Ca-IL was only one-third of that for neat ilmenite to produce the same amount of H₂ per cycle in the upscale desgin.