2024-05-02 ペンシルベニア州立大学(PennState)

<関連情報>

- https://www.psu.edu/news/engineering/story/cold-sintering-may-rescue-plastic-ceramics-battery-components-landfills/

- https://pubs.rsc.org/en/content/articlelanding/2024/mh/d3mh01976d

- https://chemistry-europe.onlinelibrary.wiley.com/doi/full/10.1002/cssc.202301920

- https://link.springer.com/article/10.1557/s43579-024-00524-9

冷間焼結によりプラスチック廃棄物を完全にリサイクル可能な複合材料にアップサイクルする Upcycling plastic waste into fully recyclable composites through cold sintering

Po-Hao Lai, Shelby L. Hall, Yi-Chen Lan, Jia-Ruey Ai, Arian Jaberi, Amir Sheikhi, Rui Shi, Bryan D. Vogt and Enrique D. Gomez

Materials Horizons Published:05 Mar 2024

DOI:https://doi.org/10.1039/D3MH01976D

Abstract

Plastics have substantial societal benefits, but their widespread use has led to a critical waste management challenge. While mechanical recycling dominates the reuse of post-consumer plastics, it is limited in efficacy, especially for composites. To address this, we propose a direct reprocessing approach that enables the creation of hybrid, long-lasting, and durable composites from difficult-to-recycle plastics. This approach utilizes cold sintering, a process that consolidates inorganic powders through fractional dissolution and precipitation at temperatures far below conventional sintering; these temperatures are compatible with plastic processing. We show that this process can create inorganic-matrix composites with significant enhancements in tensile strength and toughness over pure gypsum, which is commonly found in construction waste. These composites can be recycled multiple times through direct reprocessing with the addition of only water as a processing promoter. This approach to recycling leads to composites with orders of magnitude lower energy demand, global warming potential, and water demand, when compared against common construction products. Altogether, we demonstrate the potential for cold sintering to integrate waste into high-performance recyclable composites.

冷間焼結によりLLZOベースの複合材料の再処理が可能に Cold Sintering Enables the Reprocessing of LLZO-Based Composites

Yi-Chen Lan, Dr. Masoud Ghasemi, Shelby L. Hall, Dr. Ryan A. Fair, Christina Maranas, Prof. Rui Shi, Prof. Enrique D. Gomez

ChemSusChem Published: 24 February 2024

DOI:https://doi.org/10.1002/cssc.202301920

Graphical Abstract

Cold sintering enables direct reprocessing of composite electrolytes and provides a needed approach for promoting sustainability of energy storage devices. The low sintering temperature allows co-sintering of ceramics, polymers and lithium salts, leading to re-densification of the composite structures with reprocessing. All-solid-state lithium batteries fabricated with reprocessed electrolytes exhibit a high discharge capacity and good cycling stability.

Abstract

All-solid-state batteries have the potential for enhanced safety and capacity over conventional lithium ion batteries, and are anticipated to dominate the energy storage industry. As such, strategies to enable recycling of the individual components are crucial to minimize waste and prevent health and environmental harm. Here, we use cold sintering to reprocess solid-state composite electrolytes, specifically Mg and Sr doped Li7La3Zr2O12 with polypropylene carbonate (PPC) and lithium perchlorate (LLZO−PPC−LiClO4). The low sintering temperature allows co-sintering of ceramics, polymers and lithium salts, leading to re-densification of the composite structures with reprocessing. Reprocessed LLZO−PPC−LiClO4 exhibits densified microstructures with ionic conductivities exceeding 10−4 S/cm at room temperature after 5 recycling cycles. All-solid-state lithium batteries fabricated with reprocessed electrolytes exhibit a high discharge capacity of 168 mA h g−1 at 0.1 C, and retention of performance at 0.2 C for over 100 cycles. Life cycle assessment (LCA) suggests that recycled electrolytes outperforms the pristine electrolyte process in all environmental impact categories, highlighting cold sintering as a promising technology for recycling electrolytes.

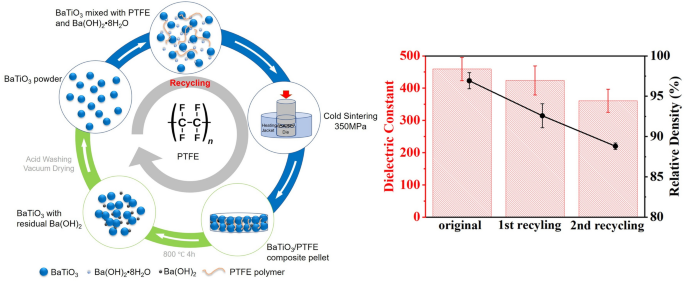

ナノサイズポリマーによるセラミック複合材料の低温焼結とリサイクル Nano-sized polymer-assisted cold sintering and recycling of ceramic composites

Juchen Zhang, Enrique D. Gomez & Hongtao Sun

MRS Communications Published:DOI:https://doi.org/10.1557/s43579-024-00524-9

Abstract

Cold sintering is an emerging technology that significantly reduces sintering temperatures by approximately an order of magnitude, down to about 100–200°C. This reduction of processing temperature enables the co-sintering and integration of dissimilar materials, such as ceramics and polymers, into unprecedented composites, where the low-energy consumption densification provides an opportunity for recycling. Here, we cold sintered barium titanate (BaTiO3)-polytetrafluoroethylene (PTFE) ceramic-polymer composites, demonstrating that nano-sized PTFE polymer powders facilitate co-sintering and enable the recycling of ceramic composites. This approach offers an opportunity for reusing and re-processing ceramic components, thereby promoting sustainability through waste reduction and energy savings.

Graphical abstract