2023-03-20 米国国立標準技術研究所(NIST)

この成果は、3Dプリントのプロフェッショナルにとって、印刷された部品の特性を予測し制御する能力を向上させ、大規模製造における一貫性と実現可能性を高めることができると期待されている。

研究により、金属の冷却速度が、その性質に影響を与えることが示された。これにより、最適な結晶構造が得られ、金属3Dプリントの成功率が向上する可能性がある。

<関連情報>

- https://www.nist.gov/news-events/news/2023/03/cracking-metal-3d-printing-conundrum-researchers-propel-technology-toward

- https://www.sciencedirect.com/science/article/pii/S1359645423000459?via%3Dihub

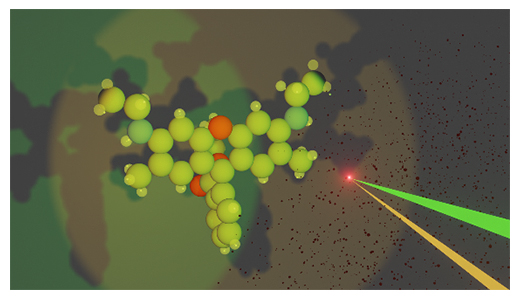

高速X線回折で明らかにした鋼材の積層造形時の凝固モード Solidification modes during additive manufacturing of steel revealed by high-speed X-ray diffraction

Hans-Henrik König, Niklas Holländer Pettersson, A. Durga, Steven Van Petegem, Daniel Grolimund, Andrew Chihpin Chuang, Qilin Guo, Lianyi Chen, Christos Oikonomou, Fan Zhang, Greta Lindwall

Acta Materialia Available online: 19 January 2023

DOI:https://doi.org/10.1016/j.actamat.2023.118713

Abstract

Solidification during fusion-based additive manufacturing (AM) is characterized by high solidification velocities and large thermal gradients, two factors that control the solidification mode of metals and alloys. Using two synchrotron-based, in situ setups, we perform high-speed X-ray diffraction measurements to investigate the impact of the solidification velocities and thermal gradients on the solidification mode of a hot-work tool steel over a wide range of thermal conditions of relevance to AM of metals. The solidification mode of primary δ-ferrite is observed at a cooling rate of 2.12 × 104 K/s, and at a higher cooling rate of 1.5 × 106 K/s, δ-ferrite is suppressed, and primary austenite is observed. The experimental thermal conditions are evaluated and linked to a Kurz-Giovanola-Trivedi (KGT) based solidification model. The modelling results show that the predictions from the multicomponent KGT model agree with the experimental observations. This work highlights the role of in situ XRD measurements for a fundamental understanding of the microstructure evolution during AM and for validation of computational thermodynamics and kinetics models, facilitating parameter and alloy development for AM processes.