2025-11-12 産業技術総合研究所

※原論文の図を引用・改変したものを使用しています。

<関連情報>

- https://www.aist.go.jp/aist_j/press_release/pr2025/pr20251112/pr20251112.html

- https://www.sciencedirect.com/science/article/abs/pii/S089268752500740X

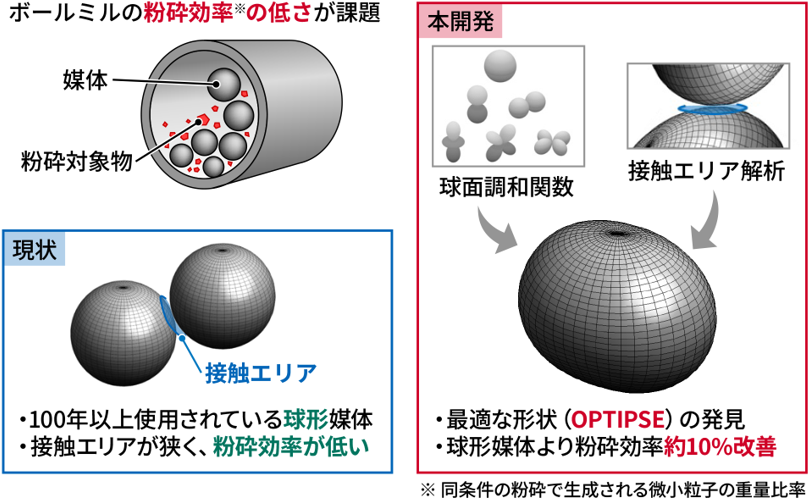

球面調和関数を用いた効率的なボールミル媒体形状設計 Efficient ball mill media shape design using spherical harmonic functions

Takao Ueda

Minerals Engineering Available online: 8 November 2025

DOI:https://doi.org/10.1016/j.mineng.2025.109912

Highlights

- Numerical simulation to generate media shape that effectively traps target object.

- The optimal shape (OPTIPSE) was a slightly flattened ellipsoid.

- Ball mill experiment with OPTIPSE improved grinding efficiency by 6.7–16%

- DEM simulation showed OPTIPSE generates greater collision force.

- OPTIPSE may replace conventional spherical media used for over a century.

Abstract

Ball mills are a standard grinding method used across various fields, and they consume vast amounts of energy while having very low grinding efficiency. Because ball mill media crush materials by sandwiching them, their efficiency is primarily governed by two factors: the probability of the media sandwiching the material, and the magnitude of the force exerted at that moment. The use of media shapes that are primarily spherical has remained unchanged for over 100 years. We hypothesized that altering the media shape could increase the probability of sandwiching materials per collision and thereby improve grinding efficiency. We used spherical harmonic functions to generate various media shapes on a computer and discovered an optimal shape, a slightly distorted ellipsoid, that could increase the probability per collision of sandwiching more material than could spheres. Subsequent analyses using the discrete element method revealed that the media with this shape generated a greater number of contact points and higher collisional forces with sand than spherical media. Experimental validation using a laboratory-scale ceramic mill with alumina media confirmed that the developed media shape improved grinding efficiency by 7–16 % compared to spherical media, without a noticeable difference in wear or damage. However, because these experimental results were based on a comparison between spheres and the developed media shape in a laboratory-scale ceramic mill, further validation at full scale under practical operating conditions will be essential prior to industrial application.