2025-09-30 パシフィック・ノースウェスト国立研究所(PNNL)

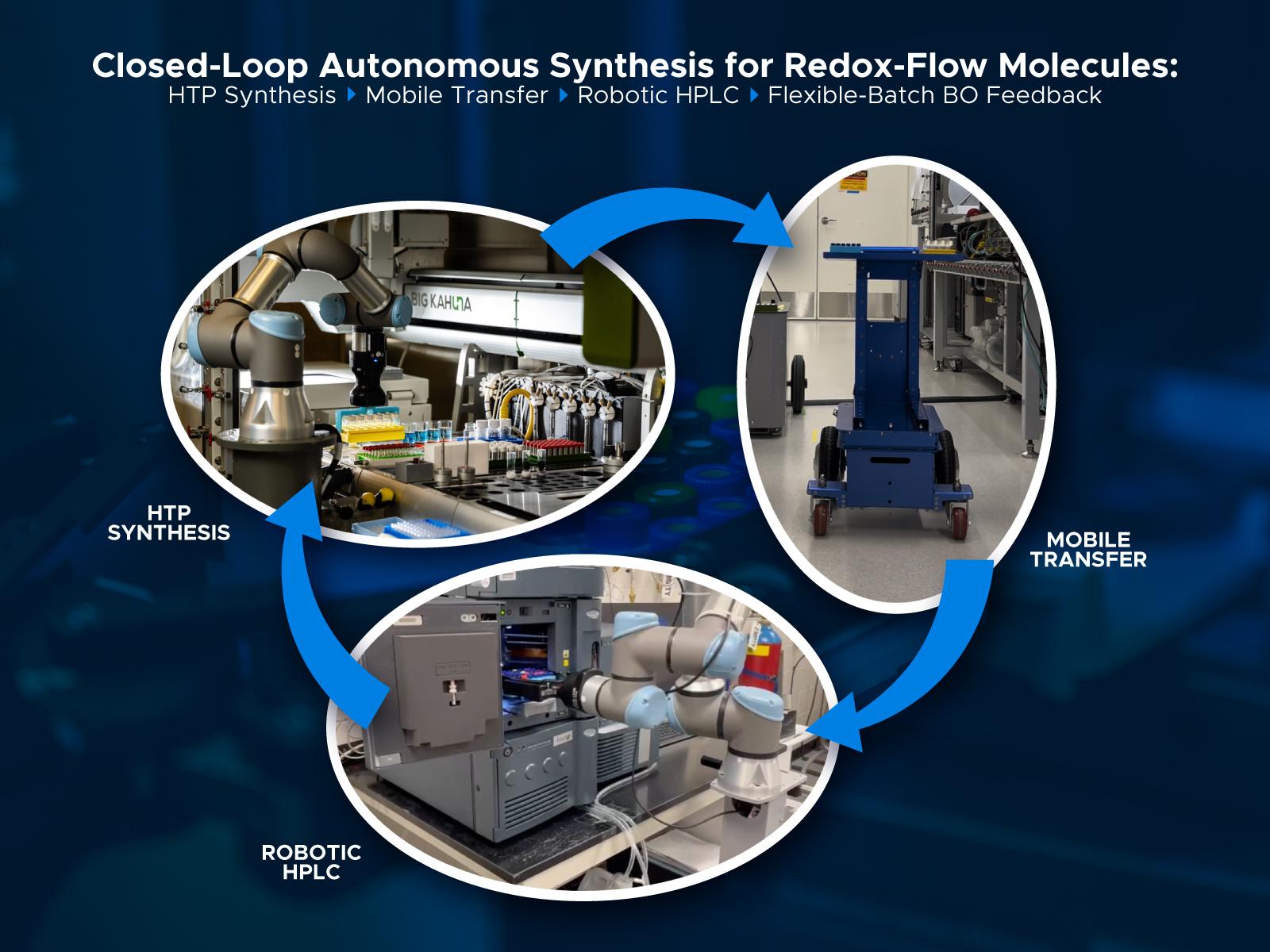

An autonomous loop executes high-throughput synthesis, performs analysis, and proposes the next experiments to accelerate science. (Image by Derek Munson | Pacific Northwest National Laboratory)

<関連情報>

- https://www.pnnl.gov/publications/autonomous-synthesis-redox-flow-batteries

- https://pubs.rsc.org/en/content/articlelanding/2025/dd/d5dd00017c

柔軟なバッチベイズ最適化 による レドックスフロー電池の自律有機合成 Autonomous organic synthesis for redox flow batteries via flexible batch Bayesian optimization

Clara Tamura, Heather Job, Henry Chang, Wei Wang, Yangang Liang and Shijing Sun

Digital Discovery Published:01 Sep 2025

DOI:https://doi.org/10.1039/D5DD00017C

Abstract

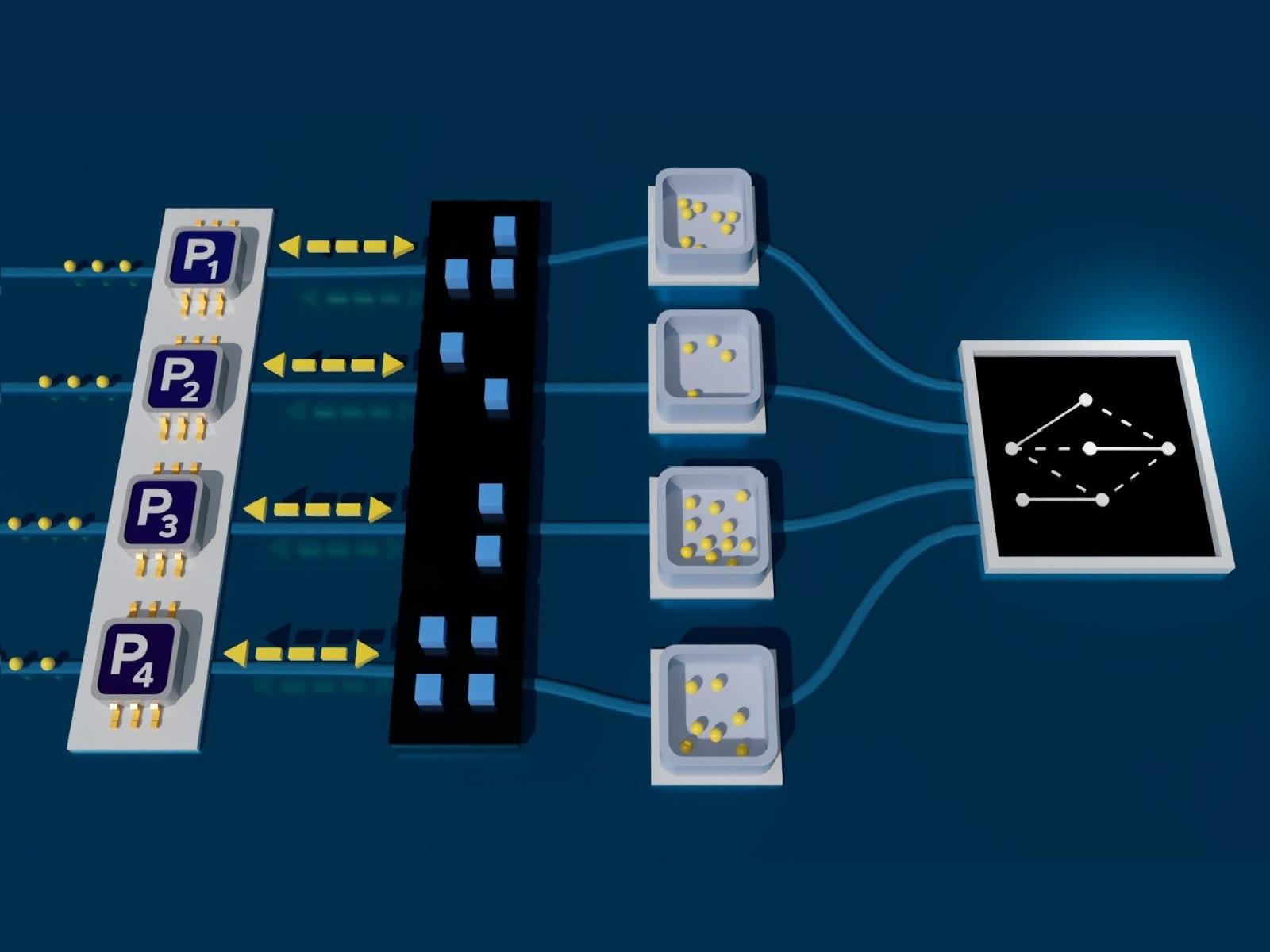

Traditional trial-and-error methods for materials discovery are inefficient to meet the urgent demands posed by the rapid progression of climate change. This urgency has driven the increasing interest in integrating robotics and machine learning into materials research to accelerate experimental learning. However, idealized decision-making frameworks to achieve maximum sampling efficiency are not always compatible with high-throughput experimental workflows inside a laboratory. For multi-step chemical processes, differences in hardware capacities can complicate the digital framework by introducing constraints on the maximum number of samples in each step of the experiment, hence causing varying batch sizes in variable selection within the same batch. Therefore, designing flexible sampling algorithms is necessary to accommodate the multi-step synthesis with practical constraints unique to each high-throughput workflow. In this work, we designed and employed three strategies on a high-throughput robotic platform to optimize the sulfonation reaction of redox-active molecules used in flow batteries. Our strategies adapt to the multi-step experimental workflow, where their formulation and heating steps are separate, causing varying batch size requirements. By strategically sampling using clustering and mixed-variable batch Bayesian optimization, we were able to iteratively identify optimal conditions that maximize the yields. Our work presents a flexible approach that allows tailoring the machine learning decision-making to suit the practical constraints in individual high-throughput experimental platforms, followed by performing resource-efficient yield optimization using available open-source Python libraries.