2025-08-20 ノースカロライナ州立大学(NCState)

<関連情報>

- https://news.ncsu.edu/2025/08/making-better-magnets/

- https://www.nature.com/articles/s41467-025-62804-9

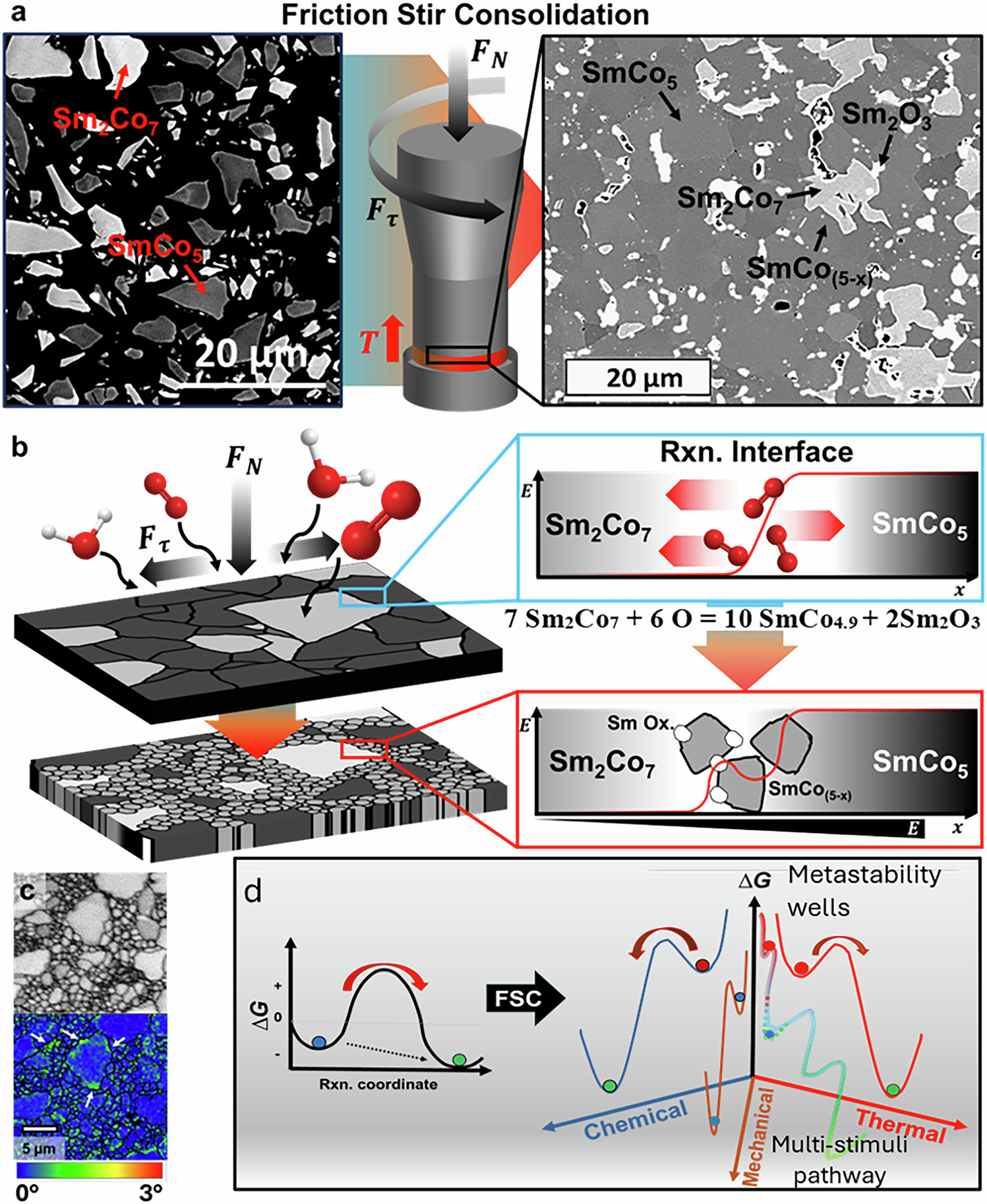

Sm-Co粉末の現場での熱・機械・化学的変換と固化を単一工程ルートにより実施した塊状磁石の製造 In-situ thermo-mechano-chemical transformation and consolidation of Sm-Co powders via a single-step route for bulk magnet fabrication

Aniruddha Malakar,Andrew Martin,Farhan Ishrak,Caleb Schenck,Anqi Yu,Mayur Pole,Jens Darsell,Tianhao Wang,Joseph Helsing,John Thornton,Michael Lastovich,Libor Kovarik,Glenn Grant,Joseph B. Tracy,Martin Thuo,Mert Efe & Bharat Gwalani

Nature Communications Published:13 August 2025

DOI:https://doi.org/10.1038/s41467-025-62804-9

Abstract

The demand for high-performance permanent magnets continues to grow across a wide range of advanced technologies. However, conventional powder metallurgy routes for rare-earth magnets such as Sm–Co are limited by the intrinsic brittleness of the powders, reducing manufacturability and yield. Here, we report a single-step, solid-state processing method—friction consolidation (FC)—that enables simultaneous deformation, heating, and chemical transformation of brittle Sm–Co powders. Using commercial SmCo₅ powders containing Sm₂Co₇, FC induces a thermo-mechano-chemical pathway in which Sm₂Co₇ undergoes oxidation to form nanoscale SmCo(5–x) (where x < 1) and Sm₂O₃ phases. The heat generated from redox reactions and adiabatic shear deformation aids densification without requiring external thermal input. The extent of phase transformation is controlled by local strain and temperature during processing, with higher deformation levels leading to enhanced Sm₂Co₇ decomposition and improved saturation magnetization. This study demonstrates that FC offers a scalable, low-temperature route to consolidate brittle magnetic powders while refining their phase composition and microstructure. By tuning the starting powder chemistry and processing atmosphere, the approach reduces unwanted secondary phases and tailors the final magnetic response—offering a new pathway to fabricate high-performance Sm–Co magnets through a compact, energy-efficient process.