2025-07-29 ロイヤルメルボルン工科大学(RMIT)

<関連情報>

- https://www.rmit.edu.au/news/all-news/2025/jul/cheaper-titanium

- https://www.nature.com/articles/s41467-025-60162-0

金属積層造形における柱状から等軸晶系への遷移を予測するための組成基準 Compositional criteria to predict columnar to equiaxed transitions in metal additive manufacturing

Ryan Brooke,Duyao Zhang,Dong Qiu,Mark A. Gibson & Mark Easton

Nature Communications Published:01 July 2025

DOI:https://doi.org/10.1038/s41467-025-60162-0

Abstract

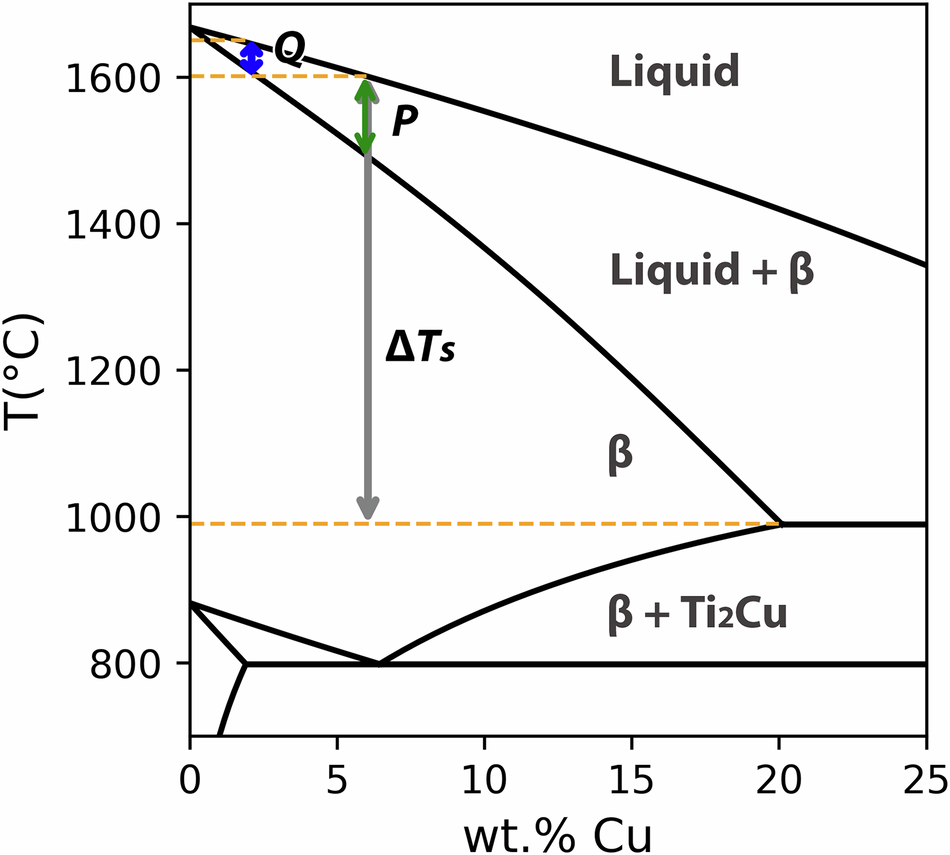

Predicting the columnar to equiaxed transition (CET) and grain refinement for additively manufactured alloys from thermodynamic databases has been a long-standing challenge and an ongoing source of discussion. Efforts are focused on designing alloy compositions to achieve fully equiaxed microstructures, thereby eliminating the mechanical anisotropy commonly associated with the large columnar grains in additively manufactured alloys. Here, three compositional parameters proposed in the literature are evaluated across a range of Ti alloys: the non-equilibrium solidification range (ΔTs), the growth restriction factor (Q) and constitutional supercooling parameter (P). Ti-Fe, Ti-Cu, Ti-Cu-Fe, and Ti-Mo alloys produced via direct energy deposition experimentally verified that P is the most reliable parameter to guide the selection of alloying elements for additively manufactured (AM) alloys. Verification was found by reconsidering results from additional alloy systems and AM methods. The numerical CET models also predict that P is closely related to dendrite tip undercooling at high growth velocities, as found in AM. This work provides a clearer framework for predicting the grain morphology of metallic alloys in AM.