2025-06-25 産業技術総合研究所

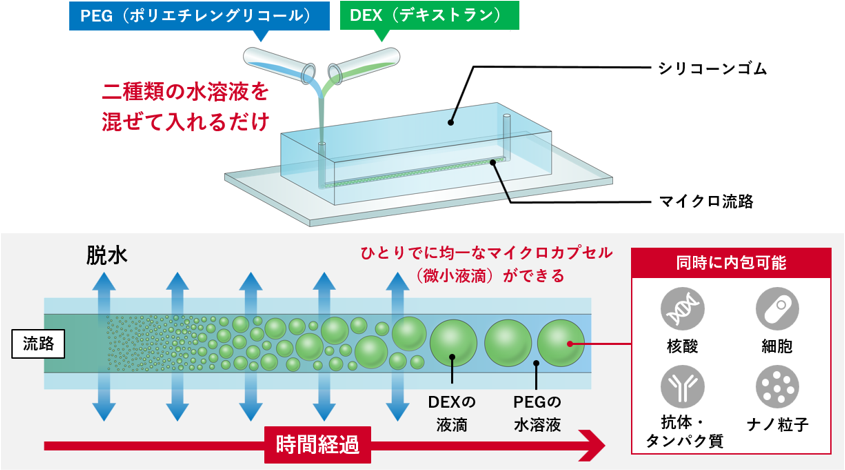

油や界面活性剤を使わず、2種類の水溶液の混合液から、薬剤成分や細胞などを内包できる微小なカプセルをつくる

油や界面活性剤を使わず、2種類の水溶液の混合液から、薬剤成分や細胞などを内包できる微小なカプセルをつくる

<関連情報>

- https://www.aist.go.jp/aist_j/press_release/pr2025/pr20250625/pr20250625.html

- https://onlinelibrary.wiley.com/doi/full/10.1002/smtd.202500387

マイクロ流体における脱水駆動相分離による均一な微小液滴のワンステップ生成のための簡便なプラットフォーム A Facile Platform for One-Step Generation of Uniform Microdroplets through Dehydration-Driven Phase Separation in Microfluidics

Ken Hirano, Mayu Shono, Akihisa Shioi, Kenichi Yoshikawa

Small Methods Published: 08 June 2025

DOI:https://doi.org/10.1002/smtd.202500387

Abstract

Microdroplet generation with the desired size is essential in various fields; however, conventional methods require complex equipment and precise flow control, limiting their accessibility. To address this challenge, this research introduces a novel and straightforward method for one-step generation of uniform, cell-sized droplets using a simple microfluidic channel made of polydimethylsiloxane (PDMS). This approach exploits the inherent water-absorption properties of PDMS to induce phase separation in a homogeneous aqueous two-phase system comprising polyethylene glycol (PEG) and dextran (DEX). Injecting a homogeneous PEG/DEX mixture below the critical concentration for phase separation into the PDMS microchannel resulted in gradual dehydration, inducing microphase separation and generating linearly arranged DEX-rich droplets within a PEG-rich continuous phase. Time-lapse observations revealed that this dehydration-driven process is gradual and controlled, producing uniform droplet sizes. The key aspects of the observed phenomena are replicated through numerical simulations using a modified Cahn–Hilliard equation that accounts for the inherent water absorption characteristics of PDMS. Furthermore, the versatility of this method is demonstrated by the successful encapsulation of various materials, such as Escherichia coli, DNA, antibodies, and nanoparticles, within the droplets. This effective technique holds promise for a wide range of applications, such as drug delivery and artificial cell engineering.