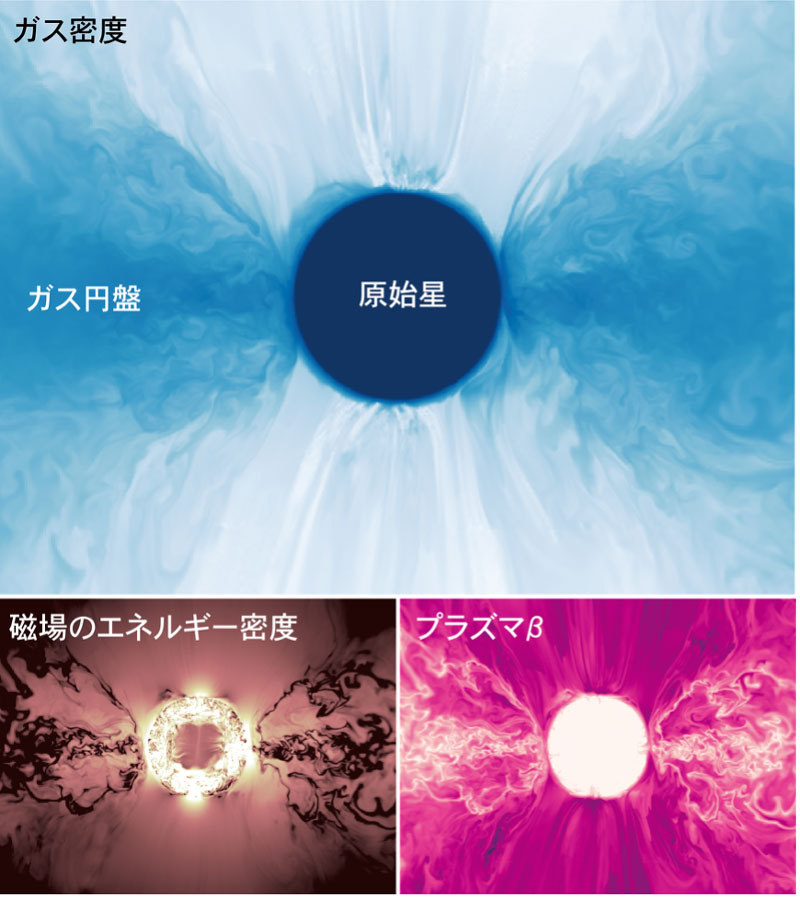

2025-05-15 京都大学

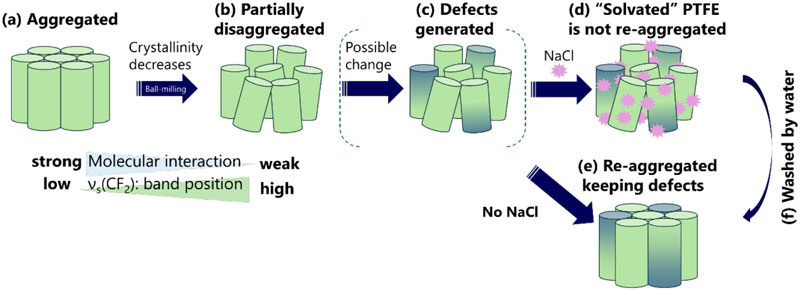

PTFE+NaClのミリング過程でおこる分子のゆるみ・欠陥とNaClの役割の概念図(「Journal of Physical Chemistry B」に掲載された論文より引用)

<関連情報>

- https://www.kyoto-u.ac.jp/ja/research-news/2025-05-15

- https://www.kyoto-u.ac.jp/sites/default/files/2025-05/web_2505_Hasegawa-f1fc32eb99bbda95b7df9e5816848fad.pdf

- https://academic.oup.com/bcsj/article/98/4/uoaf029/8120685

- https://pubs.acs.org/doi/10.1021/acs.jpcb.5c01148

NaCl結晶を用いたポリテトラフルオロエチレンのメカノケミカル加工 Mechanochemical processing of polytetrafluoroethylene with NaCl crystals

Shogo Nishimura , Yao Li , Yuta Semba , Akihide Hibara , Tomoya Oonuki , Takeshi Hasegawa , Junya Kano

Bulletin of the Chemical Society of Japan Published:28 April 2025

DOI:https://doi.org/10.1093/bulcsj/uoaf029

Abstract

Polytetrafluoroethylene (PTFE) is an indispensable material for society and industry. PTFE chains have a strong intermolecular force and form strongly bound crystal structures. The strong assembly causes a low surface energy and refractive index, as well as difficulty in processing and recycling. In this paper, we describe how PTFE powders were milled with NaCl crystals using a planetary ball mill. Furthermore, the milled PTFE-NaCl powders were immersed in water to remove NaCl, and filtered powders were obtained. These powders were characterized by X-ray diffraction (XRD) and infrared spectroscopy. The PTFE-NaCl powders had a lower XRD peak intensity than that of processed PTFE powders without NaCl. Even the filtered powders had a lower XRD peak intensity. These results suggest that the intermolecular assembly was loosened by the mechanochemical process with NaCl. Then, PTFE-NaCl and filtered powders were pressed to form pellets. The pellets were successfully sintered, while PTFE powders milled without NaCl were not.

塩化ナトリウムを用いたPTFEの分子解離過程: 赤外分光法による研究 Molecular Disaggregation Process of PTFE Using Sodium Chloride: A Study by Infrared Spectroscopy

Tomoya Oonuki,Taisuke Araki,Takayuki Oka,Hiroshi Matsuda,Nobutaka Shioya,Junya Kano,Akihide Hibara,and Takeshi Hasegawa

The Journal of Physical Chemistry B Published: April 17, 2025

DOI:https://doi.org/10.1021/acs.jpcb.5c01148

Abstract

Mechanical recycling of polytetrafluoroethylene (PTFE) has long been a crucial matter in fluorocarbon chemistry. Since the molecular aggregation of PTFE is outstandingly strong, fluorocarbon solvents are believed to be necessary for the disaggregation of PTFE, but they should not be used as much as possible because of concerns about environmental impact. Recently, a new technique using solid sodium chloride with the aid of planetary ball milling, instead of using fluorocarbon solvents, has been proposed, and this simple technique works powerfully indeed for the purpose, as confirmed by a significant decrease of crystallinity. Here, we show that the molecular disaggregation process of PTFE using sodium chloride is revealed in detail by infrared (IR) spectroscopy. The spectra clearly show that PTFE is readily crushed into fine particles, and molecular disaggregation within the particles is also recognized. These changes are not found at all in a process that does not use sodium chloride. In addition, the generation of helical defects in perfluoroalkyl chains is also found, which is correlated with molecular disaggregation. In this manner, IR spectroscopy has been found to be a useful tool in providing us rich information on the molecular disaggregation process of PTFE across three different hierarchical structures.