20025-04-03 ワシントン州立大学(WSU)

<関連情報>

- https://news.wsu.edu/press-release/2025/04/03/researchers-recycle-wind-turbine-blade-materials-to-make-improved-plastics/

- https://www.sciencedirect.com/science/article/abs/pii/S0921344925000382

風力タービンブレード廃材のマイルドケミカルリサイクルによる性能向上した熱可塑性コンポジット製造への直接再利用 Mild chemical recycling of waste wind turbine blade for direct reuse in production of thermoplastic composites with enhanced performance

Cheng Hao, Baoming Zhao, Xiaolong Guo, Shuai Zhang, Mingen Fei, Lin Shao, Wangcheng Liu, Yiding Cao, Tuan Liu, Jinwen Zhang

Resources, Conservation and Recycling Available online: 1 February 2025

DOI:https://doi.org/10.1016/j.resconrec.2025.108159

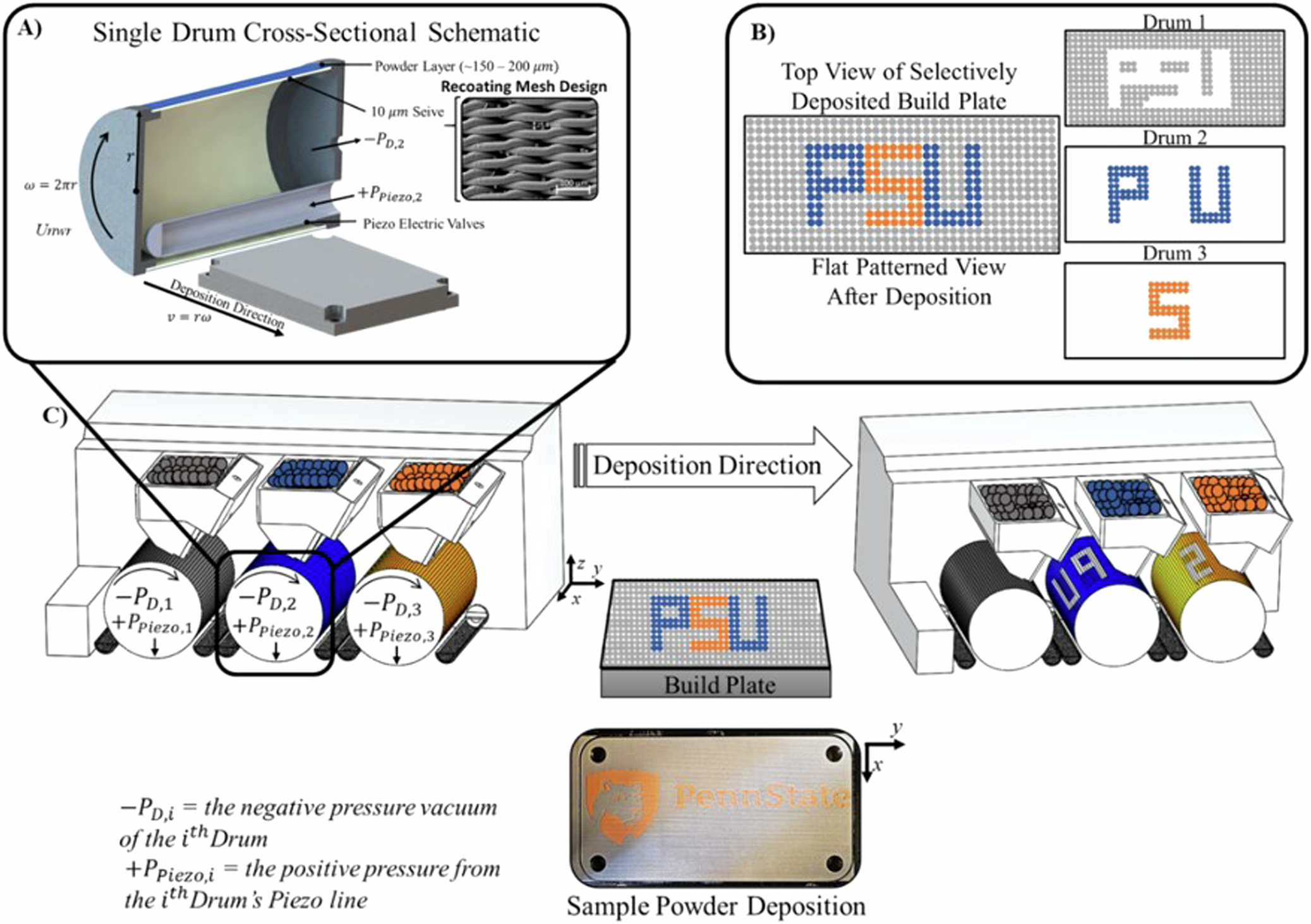

Graphical abstract

Spotlights

- Eco-friendly recycling of wind turbine GFRP waste using zinc acetate as a mild catalyst in aqueous solutions.

- Efficient recycling process with no post-degradation separation required.

- Innovative use of decomposed matrix polymer as a compatibilizer, simplifying processing and enhancing performance.

- Improved mechanical performance of rGFRP-reinforced thermoplastics, reducing reliance on virgin materials.

- Advancing recycling methods for polymer composites, promoting high-value reuse and circular economy practices.

Abstract

The increasing use of glass fiber-reinforced plastics (GFRP) in wind turbine (WT) blades poses significant recycling challenges. This study presents a mild chemical recycling method for WT GFRP waste, where the recyclates were repurposed to enhance the mechanical performance of thermoplastics. Specifically, WT GFRP waste was decomposed in aqueous solutions at temperatures ≤ 250 °C, achieving a degradation degree of up to 83.5%. The recycled GFRP (rGFRP), containing reclaimed glass fiber and decomposed matrix polymer, was directly compounded with commercial thermoplastics to produce fiber-reinforced composites. These rGFRP-reinforced thermoplastics exhibited superior mechanical properties, with tensile strength and modulus increasing from 40.4 MPa and 1.5 GPa for neat PA6 to 131.3 MPa and 15.5 GPa for composites containing 70 wt% rGFRP. This work offers a straightforward, environmentally friendly approach to recycling WT GFRP waste, providing a promising pathway for the high-value utilization of waste polymer composites.