2025-02-21 中国科学院大学(UCAS)

<関連情報>

- https://news-en.ucas.ac.cn/index.php?option=com_content&view=article&id=3222&catid=456&Itemid=413

- https://www.nature.com/articles/s41586-024-08483-w

- https://tiisys.com/blog/2025/02/15/post-161187/

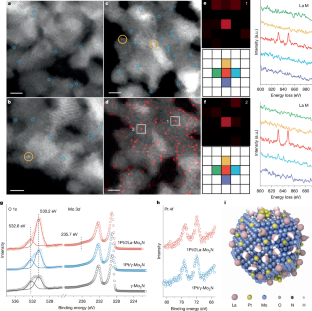

不活性ナノオーバーレイによるPt/γ-Mo2Nの遮蔽が安定したH2生成を可能にする Shielding Pt/γ-Mo2N by inert nano-overlays enables stable H2 production

Zirui Gao,Aowen Li,Xingwu Liu,Mi Peng,Shixiang Yu,Maolin Wang,Yuzhen Ge,Chengyu Li,Tie Wang,Zhaohua Wang,Wu Zhou & Ding Ma

Nature Published:12 February 2025

DOI:https://doi.org/10.1038/s41586-024-08483-w

Abstract

The use of reactive supports to disperse metal species is crucial for constructing highly efficient interfacial catalysts, by tuning the competitive reactant adsorption–activation pattern in supported metal catalysts into a non-competitive mechanism. However, these reactive supports are prone to deterioration during catalysis, limiting the lifespan of the catalyst and their potential practical applications. New strategies are needed to simultaneously protect reactive supports and surface metal species without compromising the inherent catalytic performance. Here we report a new strategy to augment the structural stability of highly active interfacial catalysts by using inert nano-overlays to partially shield and partition the surface of the reactive support. Specifically, we demonstrate that atomically dispersed inert oxide nano-overlays on a highly active Pt/γ-Mo2N catalyst can block the redundant surface sites of γ-Mo2N responsible for surface oxidation of this reactive support and the resulting deactivation. This strategy yields an efficient and highly durable catalyst for hydrogen production by methanol-reforming reaction with a mere 0.26 wt% Pt loading, exhibiting a record-high turnover number, to our knowledge, of 15,300,000 and a notable apparent turnover frequency of 24,500molH2mol−1metal h−1. This innovative approach showcases the prospects of reducing noble metal consumption and boosting longevity, which could be applied to design effective and stable heterogeneous catalysts.