2004-08-22 米国国立再生可能エネルギー研究所(NREL)

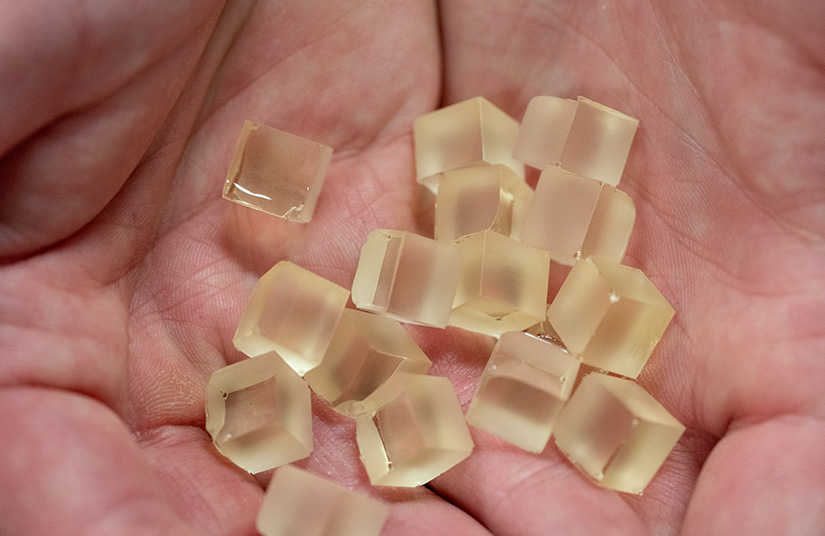

An NREL scientist holds small cubes of the PECAN resin. Photo by Werner Slocum, NREL

An NREL scientist holds small cubes of the PECAN resin. Photo by Werner Slocum, NREL

<関連情報>

- https://www.nrel.gov/news/press/2024/nrel-advances-method-for-recyclable-wind-turbine-blades.html

- https://www.science.org/doi/10.1126/science.adp5395

風力ブレードリサイクル用のバイオマス誘導可能な熱硬化性樹脂の製造と試験 Manufacture and testing of biomass-derivable thermosets for wind blade recycling

Ryan W. Clarke, Erik G. Rognerud, Allen Puente-Urbina, David Barnes, […], and Nicholas A. Rorrer

Science Published:22 Aug 2024

DOI:https://doi.org/10.1126/science.adp5395

Editor’s summary

Wind energy is a key component of the general push to power the world more sustainably. However, modern blades for use in wind turbines are assembled with epoxy resins that are resource intensive to manufacture and cannot be easily recycled. Clarke et al. report a polyester material for blade manufacture that can be derived from biomass and straightforwardly deconstructed for recycling at the end of its life by heating in methanol. Performance properties compared favorably to incumbent resins. —Jake S. Yeston

Abstract

Wind energy is helping to decarbonize the electrical grid, but wind blades are not recyclable, and current end-of-life management strategies are not sustainable. To address the material recyclability challenges in sustainable energy infrastructure, we introduce scalable biomass-derivable polyester covalent adaptable networks and corresponding fiber-reinforced composites for recyclable wind blade fabrication. Through experimental and computational studies, including vacuum-assisted resin-transfer molding of a 9-meter wind blade prototype, we demonstrate drop-in technological readiness of this material with existing manufacture techniques, superior properties relative to incumbent materials, and practical end-of-life chemical recyclability. Most notable is the counterintuitive creep suppression, outperforming industry state-of-the-art thermosets despite the dynamic cross-link topology. Overall, this report details the many facets of wind blade manufacture, encompassing chemistry, engineering, safety, mechanical analyses, weathering, and chemical recyclability, enabling a realistic path toward biomass-derivable, recyclable wind blades.