2023-12-13 バーミンガム大学

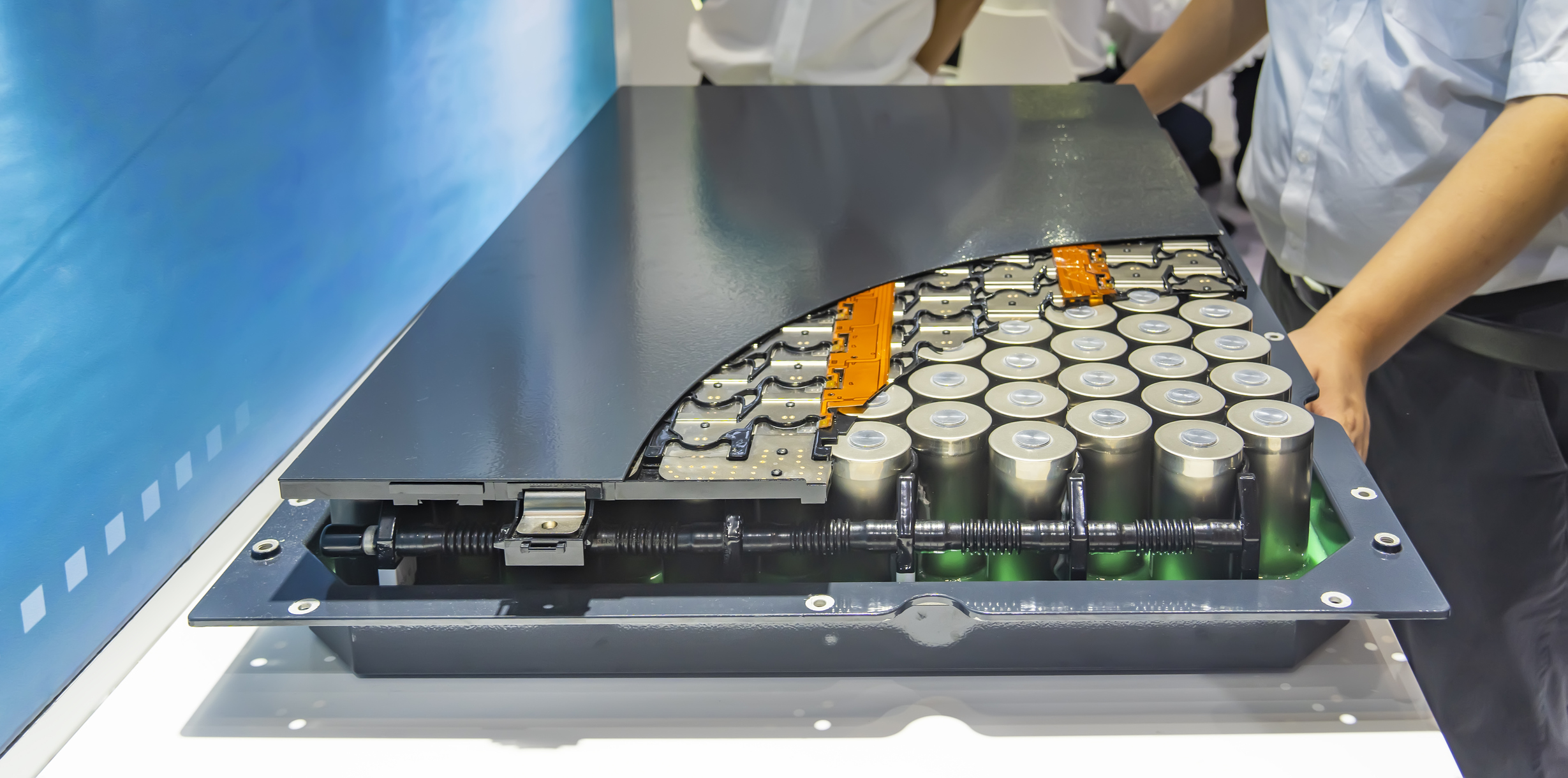

The cathode, which is the part of batteries that supply electrical current, is the primary limitation for achieving the high-energy, low-cost lithium ion (LI) batteries needed for the transition to zero emissions at tailpipe.

◆回収した材料を使用して非定型のDRX構造を持つ化合物を合成し、これが通常の層状構造よりも高いカソード容量を提供し、よりエネルギー密度の高い充電式リチウムイオンバッテリーの開発を可能にします。

◆これは再生フィードストックから初めて作られた材料であり、電気化学テストでは高性能を示しました。EVバッテリーが寿命を迎える中、そのコンポーネントをアップサイクルすることで、新しい高性能バッテリーの製造が可能になると考えられています。

<関連情報>

- https://www.birmingham.ac.uk/news/2023/upcycling-battery-materials-for-next-generation-ev-batteries

- https://chemrxiv.org/engage/chemrxiv/article-details/655c7a3edbd7c8b54bb26209

- https://chemrxiv.org/engage/chemrxiv/article-details/6530009887198ede078c2ae1

低価値の使用済み正極材料から次世代正極材料へのアップサイクル Upcycling of low value end-of-life cathode material into next generation cathode materials

Rosie Madge,Abbey Jarvis,Wilgner Lima da Silva,Laura L. Driscoll,Paul A. Anderson,Peter R. Slater

ChemRxiV Published:22 November 2023

DOI:https://doi.org/10.26434/chemrxiv-2023-hg9z8

Abstract

The increase in the use of electric vehicles (EVs) will ultimately lead to an increase in the number of end-of-life lithium-ion batteries (LIBs) that need to be recycled. A particular challenge concerns how to deal with low value cathodes, such as LiMn2O4 (LMO). To this end, this paper investigates recycling cathode material from an end-of-life Gen 1 Nissan Leaf (2011 model, 40,000 miles) which contains a mixture of spinel (LMO) and a Ni-rich layered oxide (LO). Citric acid was employed to selectively leach LMO into solution while leaving the remaining LO as a solid. The citric acid also acts as a delamination agent to remove the remaining LO from the Al current collector. The LMO was then recovered from solution and upcycled to form new cathode materials. Ni-doping of the solution allowed the synthesis of the high voltage cathode LiMn1.5Ni0.5O4 (LMNO) which is attracting commercial interest. Disordered rocksalt compounds Li4Mn2O5 and Li2MnO2.25F were also synthesised and gave a high specific discharge capacities of 293 and 279 mAh g-1 respectively. This work demonstrates a method to upcycle end-of-life cathode material into next generation cathode materials.

選択的浸出と直接リサイクルによる使用済み電気自動車混合正極の相選択的回収と再生 Phase-selective recovery and regeneration of end-of-life electric vehicle blended cathodes via selective leaching and direct recycling

Laura L Driscoll,Abbey Jarvis,Rosie Madge,Jamie-Marie Price,Rob Sommerville,Felipe Schnaider Tontini Mounib Bahr ,B. Layla Mehdi,Emma Kendrick,Nigel D Browning,Phoebe K Allan,Paul A Anderson,Peter R Slater

ChemRxiV Published:20 October 2023

DOI:https://doi.org/10.26434/chemrxiv-2023-56rkk

Abstract

Large-scale recycling and regeneration of lithium-ion cathode materials is hindered by the complex mixture of chemistries often present in the waste stream. We outline an efficient process for the separation and regeneration of phases within a blended cathode. We demonstrate the efficacy of this approach using cathode material from a first generation 1 (Gen 1) Nissan Leaf end-of-life (40,000 miles) cell. Exploiting the different stabilities of transition metals in acidic media, we demonstrate that ascorbic acid selectively leaches low-value spinel electrode material (LiMn2O4) from mixed cathode electrode (LiMn2O4 /layered Ni-rich oxide) in minutes, allowing both phases to be effectively recovered separately. This process facilitates upcycling of the Li/Mn content from the resultant leachate solution into higher-value LiNixMnyCozO2 (NMC) phases. The remaining nickel-rich layered oxide can be directly regenerated through a hydrothermal hydroxide process, which also decomposes the PVDF binder, thereby avoiding fluorine contamination of the recovered layered oxide. We report electrochemical data for the regenerated layered oxide phase while also showing that the leachate can be upcycled to next generation materials. Furthermore, while literature recycling studies are commonly performed on model systems, we illustrate here the approach on a real end of life EV battery. This study therefore illustrates a process to recycle blended cathodes containing LiMn2O4 spinel and layered Ni-rich oxide phases efficiently, with the potential to be extended to other mixed electrode waste streams. The method has great potential not only for recycling EV battery waste, but also other Li/Na ion battery waste, such as mobile phone batteries, where batteries with different cell chemistries are often be mixed.