2023-09-20 カリフォルニア工科大学(Caltech)

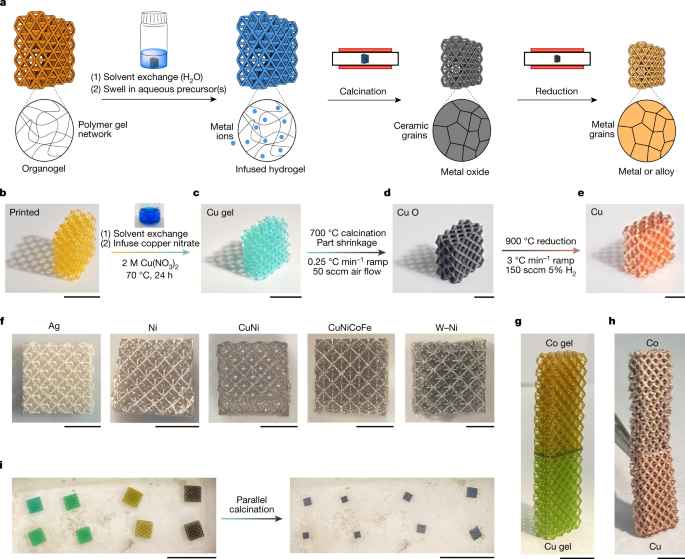

◆この技術は、カリフォルニア工科大学の研究チームによって開発され、金属構造をナノスケールで3Dプリントする最初のデモンストレーションの1つと考えられています。この技術は、触媒、エレクトロード、センサー、マイクロロボットなど、さまざまな応用分野で活用される可能性があります。

<関連情報>

- https://www.caltech.edu/about/news/technique-for-3-d-printing-metals-at-the-nanoscale-reveals-surprise-benefit

- https://www.nature.com/articles/s41586-022-05433-2

ナノスケールアディティブマニュファクチャリングが可能にする階層的微細構造を持つナノピラーにおけるサイズ効果の抑制 Suppressed Size Effect in Nanopillars with Hierarchical Microstructures Enabled by Nanoscale Additive Manufacturing

Wenxin Zhang, Zhi Li, Ruoqi Dang, Thomas T. Tran, Rebecca A. Gallivan, Huajian Gao, and Julia R. Greer

Nano Letters Published:August 29, 2023

DOI:https://doi.org/10.1021/acs.nanolett.3c02309

Abstract

Studies on mechanical size effects in nanosized metals unanimously highlight both intrinsic microstructures and extrinsic dimensions for understanding size-dependent properties, commonly focusing on strengths of uniform microstructures, e.g., single-crystalline/nanocrystalline and nanoporous, as a function of pillar diameters, D. We developed a hydrogel infusion-based additive manufacturing (AM) technique using two-photon lithography to produce metals in prescribed 3D-shapes with ∼100 nm feature resolution. We demonstrate hierarchical microstructures of as-AM-fabricated Ni nanopillars (D ∼ 130–330 nm) to be nanoporous and nanocrystalline, with d ∼ 30–50 nm nanograins subtending each ligament in bamboo-like arrangements and pores with critical dimensions comparable to d. In situ nanocompression experiments unveil their yield strengths, σ, to be ∼1–3 GPa, above single-crystalline/nanocrystalline counterparts in the D range, a weak size dependence, σ ∝ D–0.2, and localized-to-homogenized transition in deformation modes mediated by nanoporosity, uncovered by molecular dynamics simulations. This work highlights hierarchical microstructures on mechanical response in nanosized metals and suggests small-scale engineering opportunities through AM-enabled microstructures.

ハイドロゲル注入によるマイクロアーキテクト金属の積層造形 Additive manufacturing of micro-architected metals via hydrogel infusion

Max A. Saccone,Rebecca A. Gallivan,Kai Narita,Daryl W. Yee & Julia R. Greer

Nature Published:20 October 2022

DOI:https://doi.org/10.1038/s41586-022-05433-2

Abstract

Metal additive manufacturing (AM) enables the production of high value and high performance components1 with applications from aerospace2 to biomedical3 fields. Layer-by-layer fabrication circumvents the geometric limitations of traditional metalworking techniques, allowing topologically optimized parts to be made rapidly and efficiently4,5. Existing AM techniques rely on thermally initiated melting or sintering for part shaping, a costly and material-limited process6,7,8. We report an AM technique that produces metals and alloys with microscale resolution via vat photopolymerization (VP). Three-dimensional-architected hydrogels are infused with metal precursors, then calcined and reduced to convert the hydrogel scaffolds into miniaturized metal replicas. This approach represents a paradigm shift in VP; the material is selected only after the structure is fabricated. Unlike existing VP strategies, which incorporate target materials or precursors into the photoresin during printing9,10,11, our method does not require reoptimization of resins and curing parameters for different materials, enabling quick iteration, compositional tuning and the ability to fabricate multimaterials. We demonstrate AM of metals with critical dimensions of approximately 40 µm that are challenging to fabricate by using conventional processes. Such hydrogel-derived metals have highly twinned microstructures and unusually high hardness, providing a pathway to create advanced metallic micromaterials.