2025-12-16 名古屋大学

<関連情報>

- https://www.nagoya-u.ac.jp/researchinfo/result/2025/12/3d-al-fe.html

- https://www.nagoya-u.ac.jp/researchinfo/result/upload_images/20251216_engg.pdf

- https://www.nature.com/articles/s41467-025-67281-8

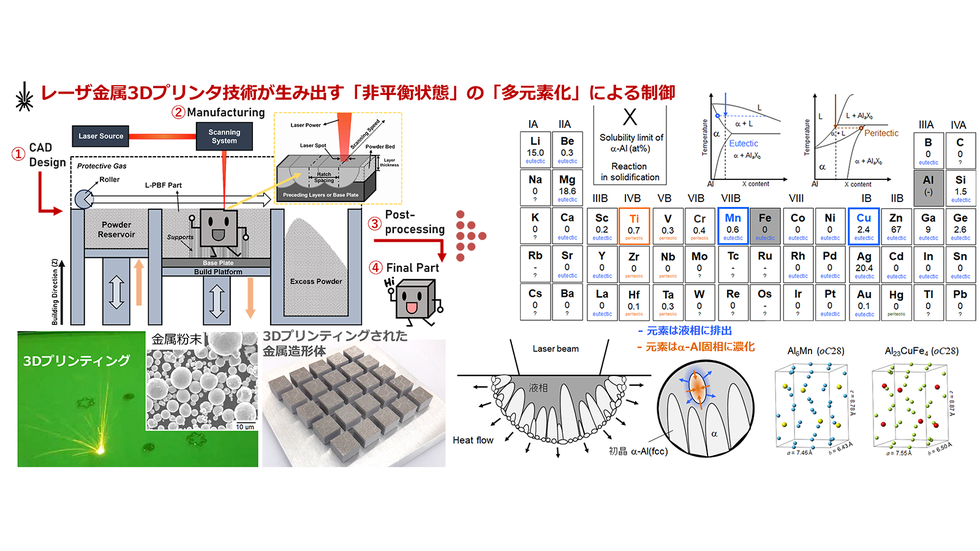

レーザー積層造形用高性能・持続可能なアルミニウム合金シリーズの設計 Design of high-performance sustainable aluminum alloy series for laser additive manufacturing

Naoki Takata,Koki Minamihama,Takanobu Miyawaki,Yue Cheng,Yifan Xu,Wenyuan Wang,Dasom Kim,Asuka Suzuki,Makoto Kobashi & Masaki Kato

Nature Communications Published:15 December 2025

DOI:https://doi.org/10.1038/s41467-025-67281-8

Abstract

Lightweight Al alloys with enhanced mechanical properties are essential for structural applications across various industries. To promote sustainable material flow, this study introduces an Al-Fe-based multi-elemental alloy series optimized for laser-based additive manufacturing (AM) using powder bed fusion (PBF-LB), leveraging recycling-friendly Al alloys with Fe as a major impurity. The alloy design is based on the concept of elemental partitioning into either the liquid phase (forming metastable Al6Fe phase for strengthening) or the solid phase (α-Al matrix) during solidification. Investigations of PBF-LB processed Al-Fe-X ternary alloys (X: Cu, Mn, and Ti) reveal the distinct roles of these alloying elements: Cu and Mn stabilize the Al6Fe phase, while Ti enhances solid-solution strengthening, in the microstructure and associated mechanical properties. Additionally, Ti promotes grain refinement by inducing the heterogeneous nucleation of nanosized Al3Ti-phase particles, leading to improved material ductility. The combined addition of alloy elements further stabilizes and strengthens the Al6Fe phase (Cu and Mn). Moreover, Mn and Ti partition independently, enabling precise control of the α-Al/Al6Fe two-phase microstructure, enhancing high-temperature mechanical performance. This study provides new insights for controlling refined metastable phases formed via PBF-LB, facilitating the development of high-performance, sustainable Al alloys for AM technologies.