2025-12-09 スウェーデン王立工科大学(KTH)

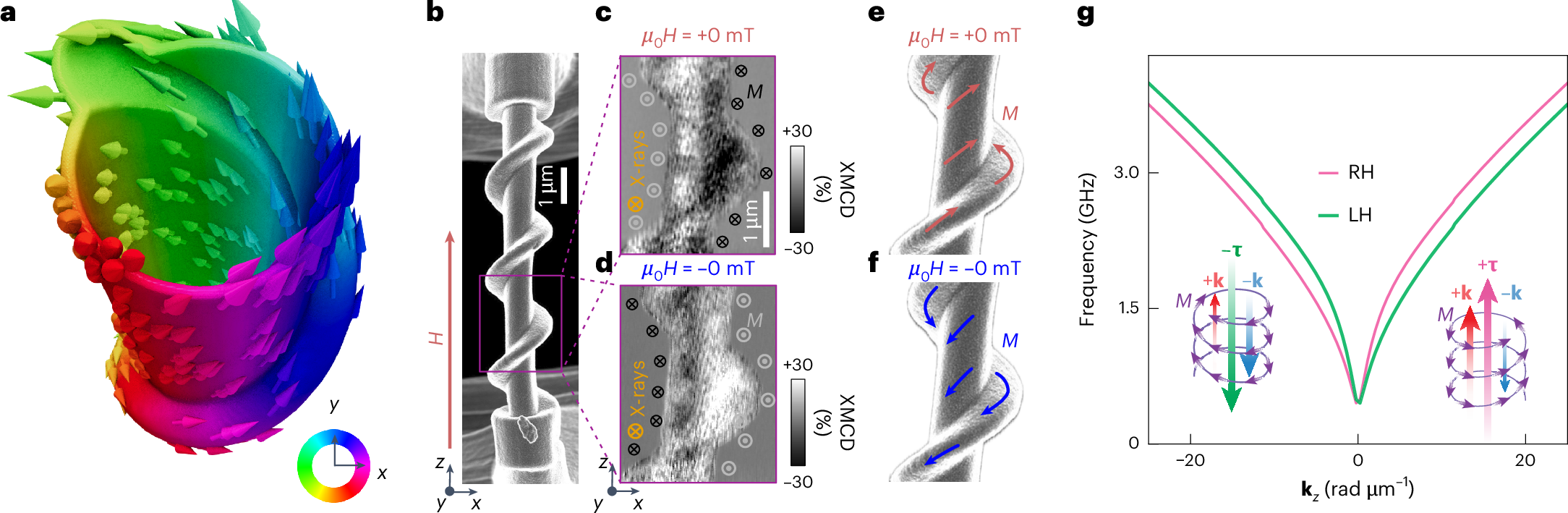

The effects of exposure to liquid lead can be seen on these sample bars of stainless steel. Photo: Kin Wing Wong

<関連情報>

- https://www.kth.se/en/om/nyheter/centrala-nyheter/study-explains-why-new-kinds-of-steel-needed-to-build-lead-cooled-reactors-1.1445534

- https://www.sciencedirect.com/science/article/pii/S0010938X25007267?via%3Dihub

移動する液体膜によって支配される不連続反応による鉛中のオーステナイトのフェライト化の機構的洞察 Mechanistic insight into the ferritization of austenite in Pb via a discontinuous reaction governed by a migrating liquid film

Kin Wing Wong, Peter Szakálos, Christopher Petersson, Dmitry Grishchenko, Pavel Kudinov

Corrosion Science Available online: 8 October 2025

DOI:https://doi.org/10.1016/j.corsci.2025.113398

Highlights

- Rapid corrosion at 500–550°C proceeds through a discontinous reaction governed by a migrating film.

- Pb films at the reaction front and Pb-rich pockets in ferrite confirms the migrating-film controlled reaction.

- Rate-limiting step shifts from Cr transport in liquid channels to metal diffusion through amorphous oxide at higher oxygen.

- Continuous erosion enhances mass transport and accelerates corrosion by shortening diffusion paths.

- Flow-induced shear may outweigh mass transfer effects in ferritization, revealing an erosion-accelerated corrosion pathway.

Abstract

The dissolution of austenitic steel in liquid lead-based alloys can induce a phase transformation characterized by a sharp dissolution front separating ferrite and austenite grains, a process commonly referred to as ferritization. Although widely reported, the mechanism driving this transformation remains under debate. This study re-examines ferritization as a discontinuous reaction via a migrating liquid film and proposes a thermodynamically consistent model for the initiation and propagation of the dissolution front. The proposed mechanism is supported by experiments at 500–550°C, literature evidence, and diffusion calculations. Under low oxygen conditions, Cr transport through liquid Pb channels is identified as the rate-limiting step, setting the theoretical corrosion rate in stagnant environments. High-speed erosion-corrosion tests show enhanced corrosion rates, driven by erosion-limited channel lengths that locally boost mass transport. In contrast, under moderate oxygen concentrations relevant for lead-cooled fast reactor (LFR) operation, the rate-limiting step shifts to metal transport across a nanometer-scale amorphous oxide layer at the reaction front. Other Ni-containing austenitic steels, including alumina-forming austenitic (AFA) alloys and Ni-based high-entropy alloys (HEAs) can also be susceptible to discontinuous reactions under direct contact with liquid Pb-based alloys, lacking the self-healing oxide protection as observed in alumina-forming ferritic steels. This limitation may present a concern for the long-term use of bare austenitic steel in liquid Pb environments.