2025-10-07 ノースカロライナ州立大学(NCState)

<関連情報>

- https://news.ncsu.edu/2025/10/cmf-resilient-high-heat/

- https://link.springer.com/article/10.1007/s10853-025-11516-y

高温での繰り返し荷重下における複合金属フォームの性能 Performance of composite metal foams under cyclic loading at elevated temperatures

Zubin Chacko,Gregory Lucier & Afsaneh Rabiei

Journal of Materials Science Published:30 September 2025

DOI:https://doi.org/10.1007/s10853-025-11516-y

Abstract

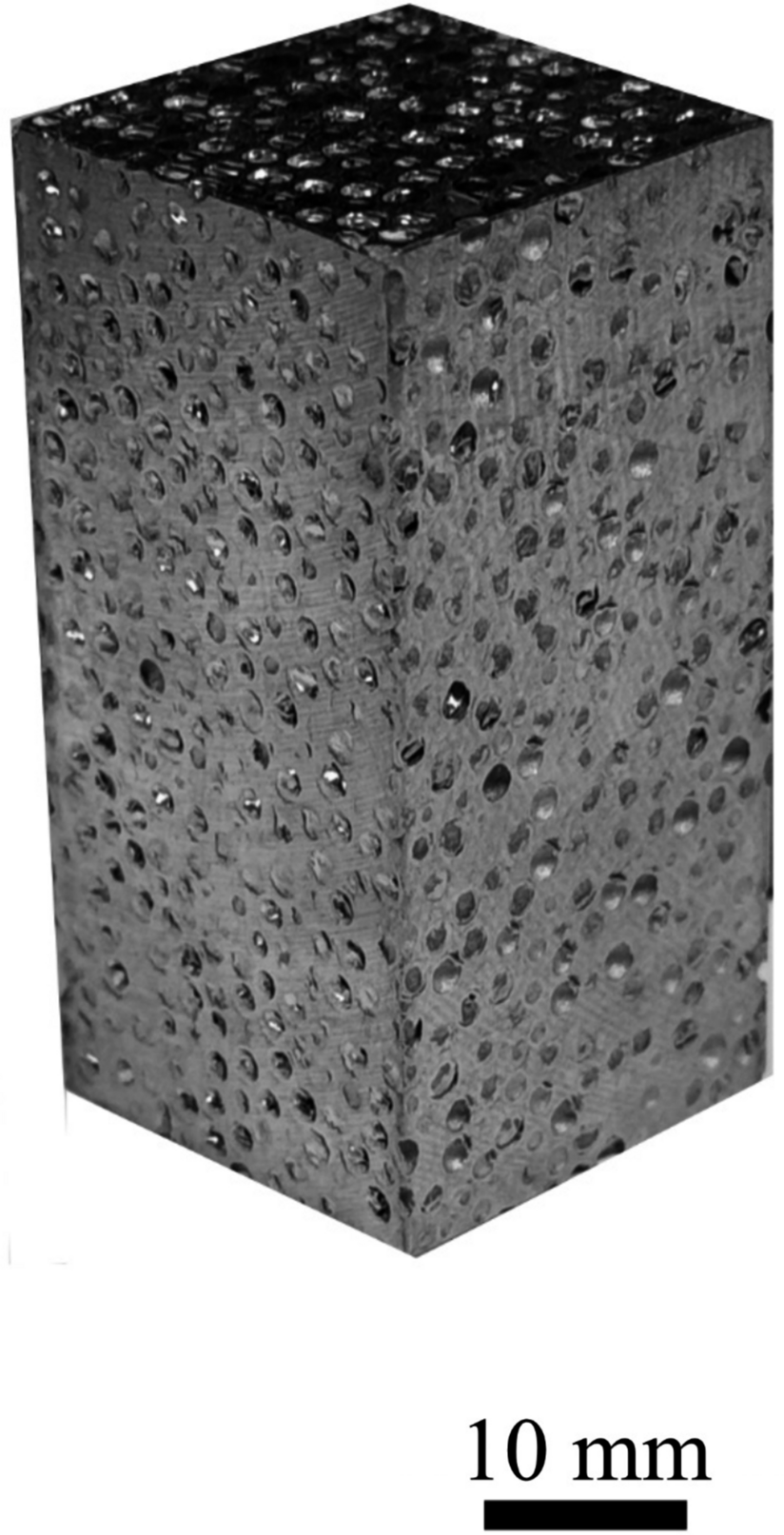

This study investigates the fatigue behavior of steel-steel composite metal foams (S–S CMFs) subjected to uniaxial compression–compression cyclic loading at 23, 400, and 600 °C to identify temperature-dependent deformation mechanisms and endurance thresholds. The S–S CMFs consist of stainless-steel hollow spheres embedded within a 316L stainless-steel matrix, designed to provide lightweight strength and thermal resistance for extreme environments. Fatigue tests of S–S CMF demonstrated a three-stage strain evolution pattern including the initial gradual strain accumulation, extended strain stability, and abrupt failure. Notably, the longest fatigue life was observed at 400 °C, where specimens remained in Stage II for over 1.3 million cycles at 60% of plateau strength (Spl), a phenomenon primarily attributed to dynamic strain aging (DSA), evidenced by serrated flow. At 600 °C, similar DSA-driven serrations occurred; however, thermal softening, dynamic recovery, and oxidation-induced damage significantly reduced fatigue life above a critical stress threshold. Scanning Electron Microscopy (SEM) revealed that the matrix porosity collapse and associated structural rearrangements played a critical role in fatigue deformation at all temperatures, contributing to the serrated features observed. Additionally, twinning observed at 600 °C suggests a thermally assisted cyclic hardening mechanism. In contrast, room-temperature fatigue was dominated by slip-driven deformation and structural porosity collapse, with smoother strain evolution. These findings highlight the complex interplay between structural (matrix porosity collapse) and dislocation-based mechanisms (DSA) in governing the fatigue response of S–S CMFs, underscoring their temperature-dependent deformation mechanisms and defining a practical endurance boundary around 50% of plateau strength.