2025-03-05 アイルランド・リムリック大学 (UL)

<関連情報>

- https://www.ul.ie/research/news/new-university-of-limerick-discovery-to-revolutionise-carbon-fibre-industry

- https://link.springer.com/article/10.1007/s42114-024-00853-2

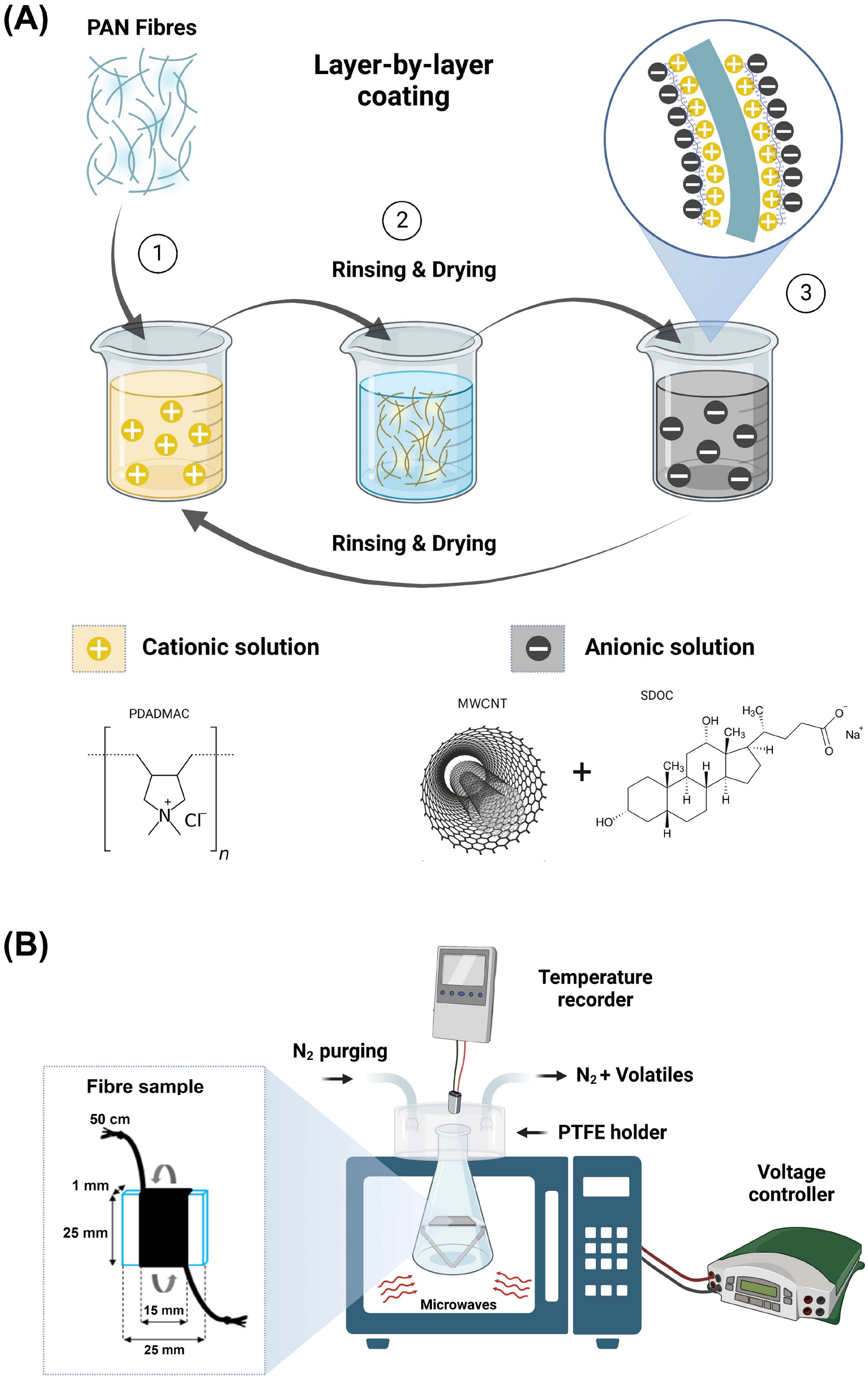

自己組織化ナノ構造コーティングが可能にするマイクロ波炭化による炭素繊維製造の環境負荷低減 Decreasing the environmental impact of carbon fibre production via microwave carbonisation enabled by self-assembled nanostructured coatings

Michał A. Stróżyk,Muhammad Muddasar,Timothy J. Conroy,Frida Hermansson,Matty Janssen,Magdalena Svanström,Erik Frank,Mario Culebras & Maurice N. Collins

Advanced Composites and Hybrid Materials Published:23 February 2024

DOI:https://doi.org/10.1007/s42114-024-00853-2

Abstract

The use of carbon fibre (CF)-based composites is of growing global importance due to their application in high-end sectors such as aerospace, automotive, construction, sports and leisure amongst others. However, their current high production cost, high carbon footprint and reduced production capability limit their use to high-performance and luxury applications. Approximately 50% of the total cost of CF production is due to the thermal conversion of polyacrylonitrile (PAN) precursor fibre (PF) to CF as it involves the use of high energy consumption and low heating efficiency in large furnaces. Looking at this scenario, this study proposes in the present study to use microwave (MW) heating to convert PF to CF. This is scientifically and technologically challenging since PF does not absorb microwave energy. While MW plasma has been utilised to carbonise fibres, it is the high temperature from the plasma that does the carbonisation and not the MW absorption of the fibres. Therefore, for the first time, this research shows how carbonisation temperatures of >1000 °C can be reached in a matter of seconds through the use of a novel microwave (MW) susceptor nanocoating methodology developed via a layer-by-layer assembly of multiwall carbon nanotubes (MWCNTs) on the PF surface. Remarkably, these CFs can be produced in an inexpensive domestic microwave and exhibit mechanical performance equivalent to CF produced using conventional heating. Additionally, this study provides a life cycle and environmental impact analysis which shows that MW heating reduces the energy demand and environmental impact of lignin-based CF production by up to 66.8% and 69.5%, respectively.