2024-07-18 オークリッジ国立研究所(ORNL)

<関連情報>

- https://www.ornl.gov/news/free-3d-printing-datasets-enable-analysis-confidence-printed-parts

- https://www.mdpi.com/1996-1944/16/23/7293

レーザー粉末床融合部品の直接局所引張特性予測のためのデータ駆動型フレームワーク A Data-Driven Framework for Direct Local Tensile Property Prediction of Laser Powder Bed Fusion Parts

Luke Scime,Chase Joslin,David A. Collins,Michael Sprayberry,Alka Singh,William Halsey,Ryan Duncan,Zackary Snow,Ryan Dehoff and Vincent Paquit

Materials Published: 23 November 2023

DOI:https://doi.org/10.3390/ma16237293

Abstract

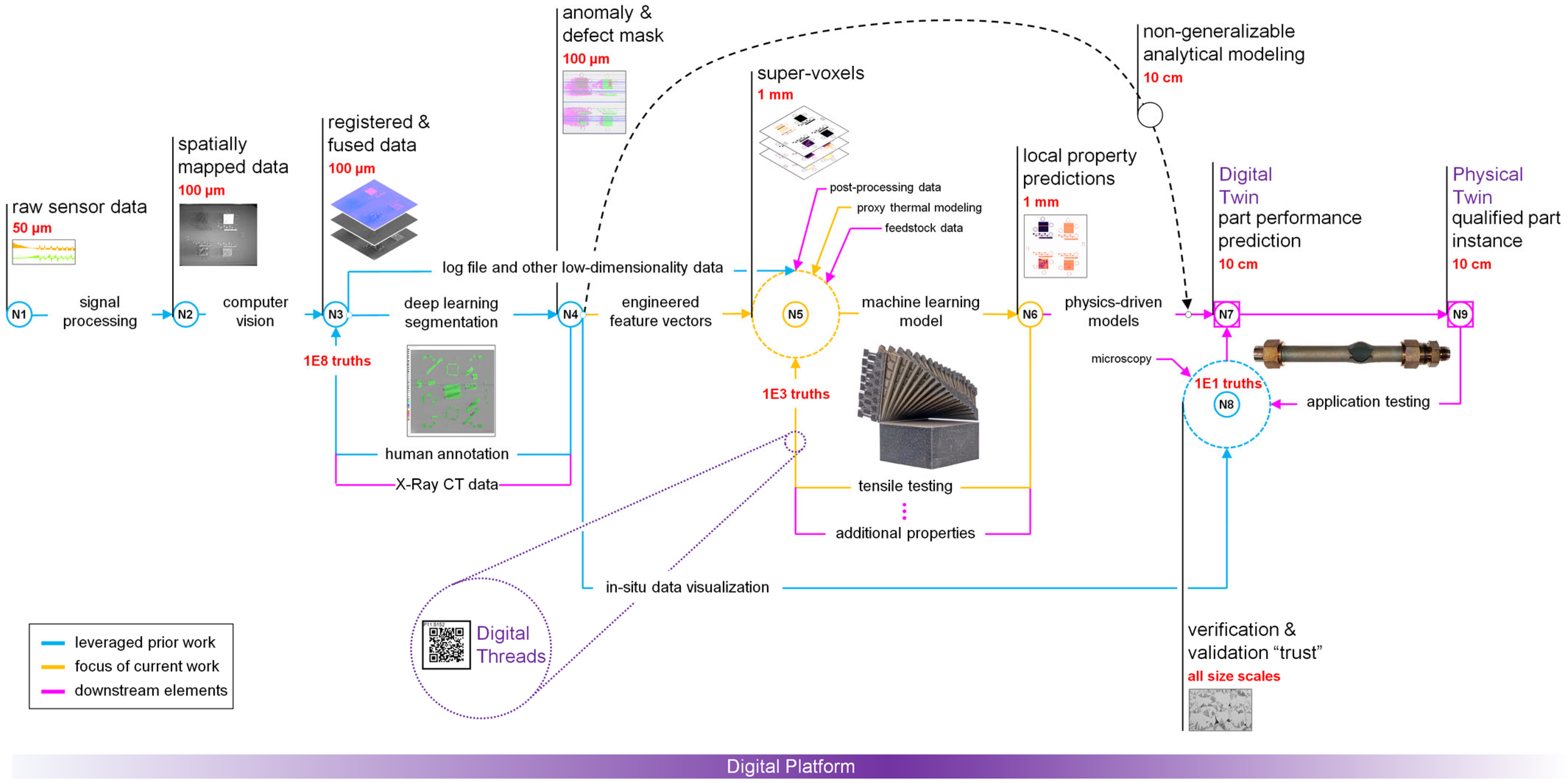

This article proposes a generalizable, data-driven framework for qualifying laser powder bed fusion additively manufactured parts using part-specific in situ data, including powder bed imaging, machine health sensors, and laser scan paths. To achieve part qualification without relying solely on statistical processes or feedstock control, a sequence of machine learning models was trained on 6299 tensile specimens to locally predict the tensile properties of stainless-steel parts based on fused multi-modal in situ sensor data and a priori information. A cyberphysical infrastructure enabled the robust spatial tracking of individual specimens, and computer vision techniques registered the ground truth tensile measurements to the in situ data. The co-registered 230 GB dataset used in this work has been publicly released and is available as a set of HDF5 files. The extensive training data requirements and wide range of size scales were addressed by combining deep learning, machine learning, and feature engineering algorithms in a relay. The trained models demonstrated a 61% error reduction in ultimate tensile strength predictions relative to estimates made without any in situ information. Lessons learned and potential improvements to the sensors and mechanical testing procedure are discussed.