2024-05-01 ロイヤルメルボルン工科大学(RMIT)

<関連情報>

- https://www.rmit.edu.au/news/all-news/2024/may/pole-top-fires

- https://link.springer.com/article/10.1007/s42114-024-00874-x

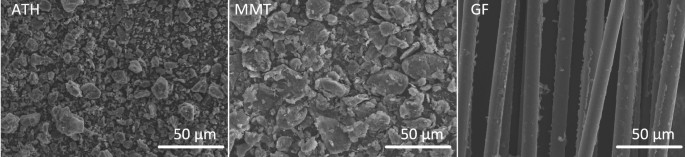

水酸化アルミニウム、粘土、ガラス繊維の添加剤により、シリコーンゴム複合絶縁体の難燃性と表面放電耐性を高める Enhancing flame and electrical surface discharge resistance in silicone rubber composite insulation through aluminium hydroxide, clay, and glass fibre additives

M. Tariq Nazir,Arslan Khalid,Cheng Wang,Imrana Kabir,Guan H. Yeoh &B. Toan Phung

Advanced Composites and Hybrid Materials Published:15 March 2024

DOI:https://doi.org/10.1007/s42114-024-00874-x

Abstract

Silicone rubber (SR) is a leading polymer used in electrical outdoor insulation applications due to its superior hydrophobic characteristics. However, the low flame and electrical surface discharge resistance of SR limit its broad viability and challenge its integrity in severe outdoor working conditions. This work attempts to explore the flame retardancy and surface discharge characteristics of SR co-filled with aluminium hydroxide (ATH), nanoclay montmorillonite (MMT), and chopped glass fibre (GF). Results indicate that the incorporation of ATH/MMT/GF could assist in improving the fire and surface discharge resistance of the SR material. It is noted that the maximum average rate of heat emission (MARHE) and total smoke production (TSP) are measured at 24.93 kW/m2 and 0.48 m2 in SRE, relative to 61.29 kW/m2 and 6.02 m2 in SRB. Using finite element analysis (FEA), the maximum electric field strength is computed at 4.66 × 106 V/m in the air gap coupled with a high-voltage (HV) plate and sample. SRE exhibits a higher partial discharge inception voltage (PDIV) value of 2.32 kVrms than its counterparts, while the maximum discharge magnitude (Qmax) is computed at 7095 pC, relative to 7746 pC in SRB. SRE emerges as a preferable SR composite to be used in electrical insulation applications with excellent flame and surface discharge resistance characteristics.