2024-04-25 米国国立再生可能エネルギー研究所(NREL)

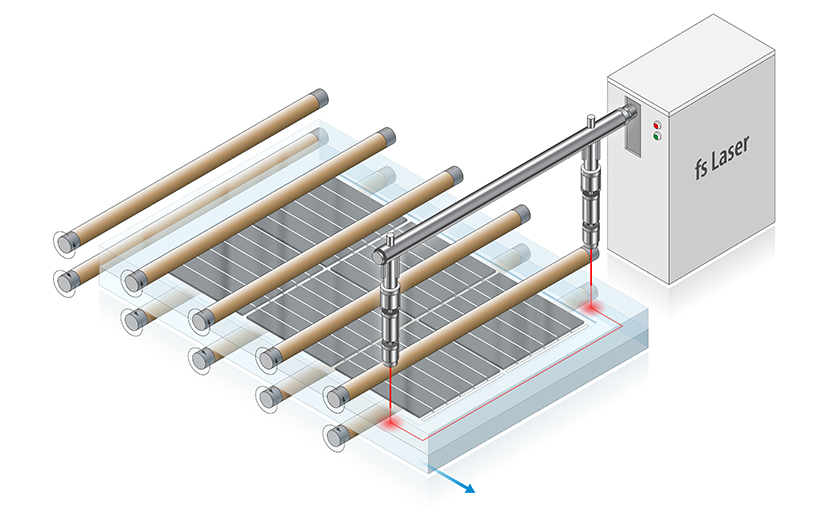

The use of a laser to weld the edges of glass together can help make solar panels easier to recycle at the end of their lifespan. Graphic by Al Hicks

<関連情報>

- https://www.nrel.gov/news/press/2024/nrel-proof-of-concept-shows-path-to-easier-recycling-of-solar-modules.html

- https://ieeexplore.ieee.org/document/10443029

ポリマーフリーのフェムト秒レーザー溶接ガラス/ガラス太陽電池モジュールに向けて Towards Polymer-Free, Femto-Second Laser-Welded Glass/Glass Solar Modules

David L. Young; Timothy J. Silverman; Nicholas P. Irvin,…

IEEE Journal of Photovoltaics Date of Publication: 21 February 2024

DOI:https://doi.org/10.1109/JPHOTOV.2024.3364823

Abstract

This article explores the use of femtosecond (fs) lasers to form glass-to-glass welds for hermetically sealed, polymer-free solar modules. Low-iron solar glass coupons were welded together without the use of glass filler using a fs laser with dedicated optics to elongate the focal plane parallel to the incident beam. The resulting welds were then stress tested to failure to reveal the critical stress intensity factor, KIc . These values were used in a structural mechanics model of a 1 m × 2 m glass/glass module under a simulated static load test. The results show that the fs laser welds are strong enough for a suitably framed module to pass the IEC 61215 static load test with a load of 5400 Pa. Key to this finding is that the module must be framed and braced, and the glass must be ribbed to allow pockets for the cells and welds inside the border of the module. The result is a module design that is completely polymer free, hermetically sealed, has improved thermal properties, and is easily recycled.