2025-10-08 スイス連邦工科大学ローザンヌ校(EPFL)

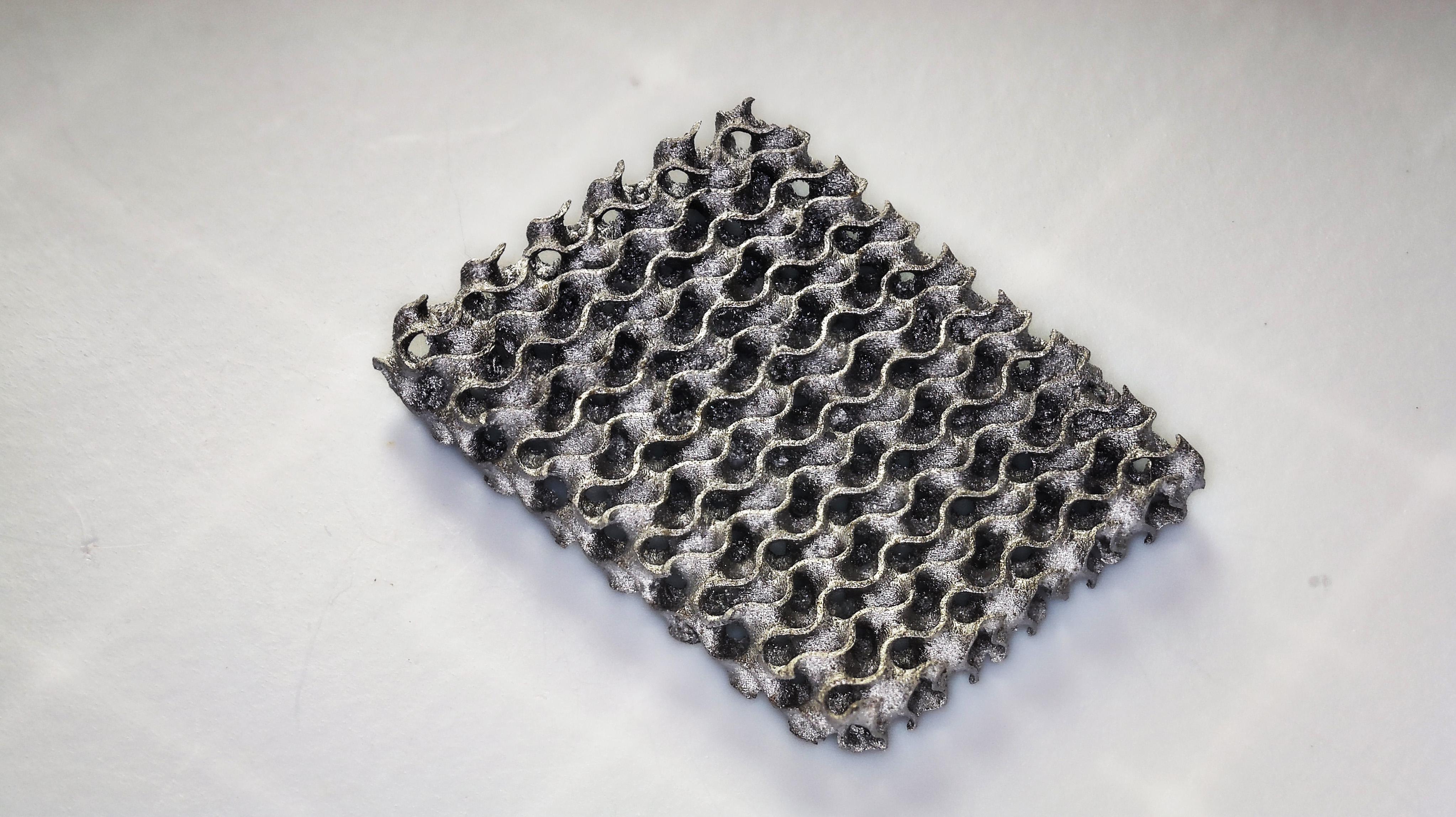

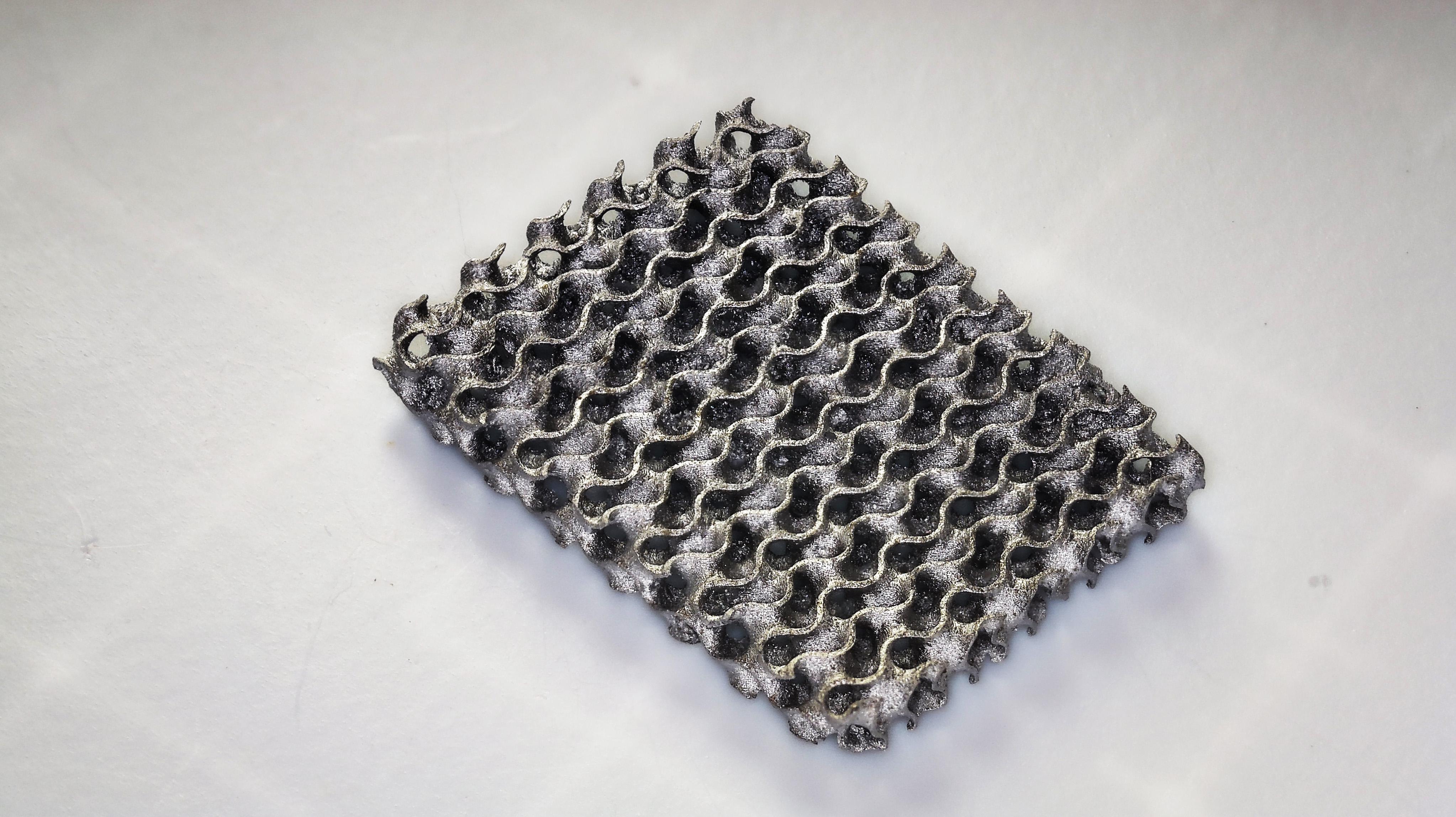

大型鉄ジャイロイド(1.3 x 1.0 cm)ALCHEMY EPFL CC BY SA

大型鉄ジャイロイド(1.3 x 1.0 cm)ALCHEMY EPFL CC BY SA

<関連情報>

- https://actu.epfl.ch/news/new-3d-printing-method-grows-ultra-strong-materi-2/

- https://advanced.onlinelibrary.wiley.com/doi/10.1002/adma.202504951

繰り返し注入沈殿法による低収縮のセラミックスおよび金属のハイドロゲルベースバット光重合 Hydrogel-Based Vat Photopolymerization of Ceramics and Metals with Low Shrinkages via Repeated Infusion Precipitation

Yiming Ji, Ying Hong, Dhruv R. Bhandari, Daryl W. Yee

Advances Materials Published: 24 September 2025

DOI:https://doi.org/10.1002/adma.202504951

Abstract

Vat photopolymerization (VP) is a powerful tool for the fabrication of architected ceramic and metal structures. However, conventional methods of ceramic/metal VP, such as with the use of slurries or organic–inorganic hybrid resins, have challenges with viscosities, light-scattering, and limited material compositions. Recently, the use of metal-salt solutions has emerged as a promising approach for the VP of ceramics and metals. While versatile and accessible, the process is accompanied by a significant amount of shrinkage, which causes warping, porosity, and structural damage. Here, a versatile method is presented for fabricating dense architected ceramics and metals with low conversion linear shrinkages. Central to this method is a post-fabrication repeated infusion-coprecipitation process that progressively increases the metal loading in the 3D “blank” hydrogels. Thermal treatment of these high metal content hydrogels then converts them into ceramic or metal architectures. To demonstrate the versatility of this approach, a variety of 3D ceramic and metal structures with shrinkages as low as 20% while maintaining densities >80% is fabricated. This infusion-precipitation-based process thus enables the VP of high-quality ceramics and metals, which is necessary for the fabrication of advanced architected materials and devices.