2024-09-19 ロイヤルメルボルン工科大学(RMIT)

<関連情報>

- https://www.rmit.edu.au/news/all-news/2024/sep/liquid-metal-ammonia

- https://www.nature.com/articles/s41929-024-01219-z

アンモニア合成用液体Cu-Ga触媒の金属移動度を解明 Unveiling metal mobility in a liquid Cu–Ga catalyst for ammonia synthesis

Karma Zuraiqi,Yichao Jin,Caiden J. Parker,Jaydon Meilak,Nastaran Meftahi,Andrew J. Christofferson,Salvy P. Russo,Michelle J. S. Spencer,Huai Yong Zhu,Lizhuo Wang,Jun Huang,Rosalie K. Hocking,Ken Chiang,Sarina Sarina & Torben Daeneke

Nature Catalysis Published:19 September 2024

DOI:https://doi.org/10.1038/s41929-024-01219-z

Abstract

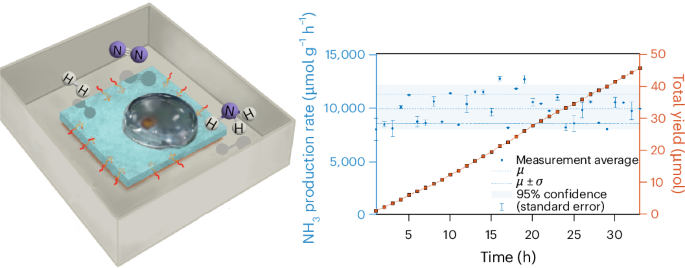

The outlook for sustainable economic and ecological growth projects an ammonia economy as a key enabler to the energy transition landscape. The predominance of the Haber–Bosch process, however, as the current industrial process for producing ammonia subdues the sustainability of establishing an energy route predicated on ammonia. Here we capitalize on the inherent atomic structure of liquid metal alloys and the ability to modulate the electronic and geometric structures of liquid metal catalysts to drive the thermocatalytic synthesis of ammonia. By exploiting the mobility of the metal atoms in the liquid metal configuration and purposefully designing disordered metal catalysts, we provide insights into designing future transition metal-based catalysts that produce ammonia from gaseous nitrogen and hydrogen under mild operating conditions. The use of a molten Cu–Ga catalyst offers a dynamic metal complex with synergistic advantages that lift the activity of its constituent elements, exceeding the activity of a control Ru-based catalyst.