2025-10-20 ワシントン州立大学(WSU)

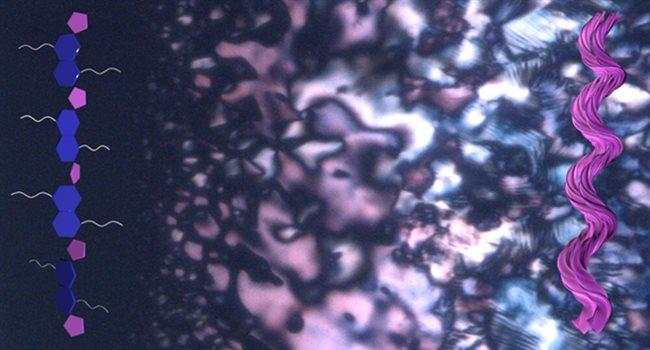

A chip-sized processor and 3D-printed antenna array developed by WSU researchers could someday lead to flexible and wearable wireless systems and improved electronic communications in a wide variety of applications (composite featuring photo courtesy of WSU and illustration by coffeemill on Adobe Stock).

<関連情報>

- https://news.wsu.edu/press-release/2025/10/20/3d-printed-antenna-arrays-developed-for-flexible-wireless-systems/

- https://www.nature.com/articles/s41467-025-64135-1

オンチップの迅速な洞察生成機能を備えた、動的ビーム安定化、付加印刷フレキシブルアンテナアレイ Dynamic beam-stabilized, additive-printed flexible antenna arrays with on-chip rapid insight generation

Sreeni Poolakkal,Abdullah Islam,Arpit Rao,Shrestha Bansal,Ted Dabrowski,Kalsi Kwan,Zhongxuan Wang,Amit Kumar Mishra,Julio A. Navarro,Shenqiang Ren,John D. Williams,Sudip Shekhar & Subhanshu Gupta

Nature Communications Published:14 October 2025

DOI:https://doi.org/10.1038/s41467-025-64135-1

Abstract

Conformal phased arrays promise shape-changing properties, multiple degrees of freedom in the scan angle, and applications for edge computing, including devices for wearable, airborne, and seaborne platforms. However, they have suffered from two critical limitations. (1) Although most applications require on-the-move communication and sensing, prior conformal arrays have suffered from dynamic deformation-induced beam pointing errors. This work introduces a dynamic beam-stabilized processor capable of beam adaptation through on-chip real-time control of fundamental gain, phase, and delay for each element. (2) Prior conformal arrays have leveraged additive printing to enhance flexibility, but conventional printable inks based on silver are expensive, and those based on copper suffer from spontaneous metal oxidation that alters trace impedance and degrades beamforming performance. Instead, we leverage a low-cost copper molecular decomposition ink with < 0.1% variation per °C across temperature and strain, and corrects any residual deformity in real-time using the dynamic beam-stabilized processor. Demonstrating unified material and physical deformation correction, our silicon-integrated dynamic beam-stabilized processor is low-power, low-area, and easily scalable due to tile-based architecture, thereby ideal for on-device implementations.