<関連情報>

- https://www.psu.edu/news/engineering/story/making-rechargeable-batteries-more-sustainable-fully-recyclable-components/

- https://pubs.acs.org/doi/10.1021/acsenergylett.4c01153

- https://onlinelibrary.wiley.com/doi/abs/10.1002/adfm.201602489

全固体リチウム電池のリサイクル性を可能にする界面層 Interfacial Layers to Enable Recyclability of All-Solid-State Lithium Batteries

Yi-Chen Lan, Po-Hao Lai, Bryan D. Vogt, and Enrique D. Gomez

ACS Energy Letters Published:June 12, 2024

DOI:https://doi.org/10.1021/acsenergylett.4c01153

Abstract

All-solid-state batteries provide opportunities for safe and robust energy storage solutions. An emerging issue is the final disposal of spent batteries due to the required production scale, limited lifetime, and lack of recycling methods. Here, we propose an architectural design for recyclable all-solid-state lithium batteries based on interfacial layers at the electrodes. Flexible lithium bis(fluorosulfonyl)imide doped polypropylene carbonate (PPC-LiFSI) interfacial layers improve physical contacts at Li metal and Li7La3Zr2O12 (LLZO)-based composite electrolytes interfaces and serve as sacrificial layers to enable clean separation and direct recycling. Recovered components demonstrate the preservation of electrochemical properties through direct reintegration into batteries. Fully recovered full cells with Li-metal and LTO anodes show 92.5% and 93.8% of original discharge capacity at 0.05 C and room temperature. We demonstrate an approach for the design of recyclable all-solid-state lithium batteries to fulfill long-term goals for sustainable energy storage devices.

複合材料の冷間焼結プロセス:セラミック材料とポリマー材料の加工温度ギャップを埋める Cold Sintering Process of Composites: Bridging the Processing Temperature Gap of Ceramic and Polymer Materials

Jing Guo, Seth S. Berbano, Hanzheng Guo, Amanda L. Baker, Michael T. Lanagan, Clive A. Randall

Advanced Functional Materials Published: 18 August 2016

DOI:https://doi.org/10.1002/adfm.201602489

Abstract

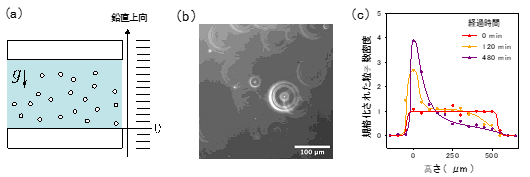

Co-sintering ceramic and thermoplastic polymer composites in a single step with very high volume fractions of ceramics seems unlikely, given the vast differences in the typical sintering temperatures of ceramics versus polymers. These processing limitations are overcome with the introduction of a new sintering approach, namely “cold sintering process” (CSP). CSP utilizes a transient low temperature solvent, such as water or water with dissolved solutes in stoichiometric ratios consistent with the ceramic composition, to control the dissolution and precipitation of ceramics and effect densification between room temperature and ≈200 °C. Under these conditions, thermoplastic polymers and ceramic materials can be jointly formed into dense composites. Three diphasic composite examples are demonstrated to show the overall diversity of composite material design between organic and inorganic oxides, including the microwave dielectric Li2MoO4–(C2F4 ) n , electrolyte Li1.5Al0.5Ge1.5(PO4)3–(CH2CF2 ) x [CF2CF(CF3)] y , and semiconductor V2O5–poly(3,4-ethylenedioxythiophene) polystyrene sulfonate composites. Cold sintering is more general and shall have a major impact on the processing of composite materials for many different applications, mechanical, thermal, and electronic, to mention a few possibilities. CSP concepts open up new composite material design and device integration schemes, impacting a wide variety of applications.