(Researchers print, tune graphene sensors to monitor food freshness, safety)

2020/6/25 アイオワ州立大学

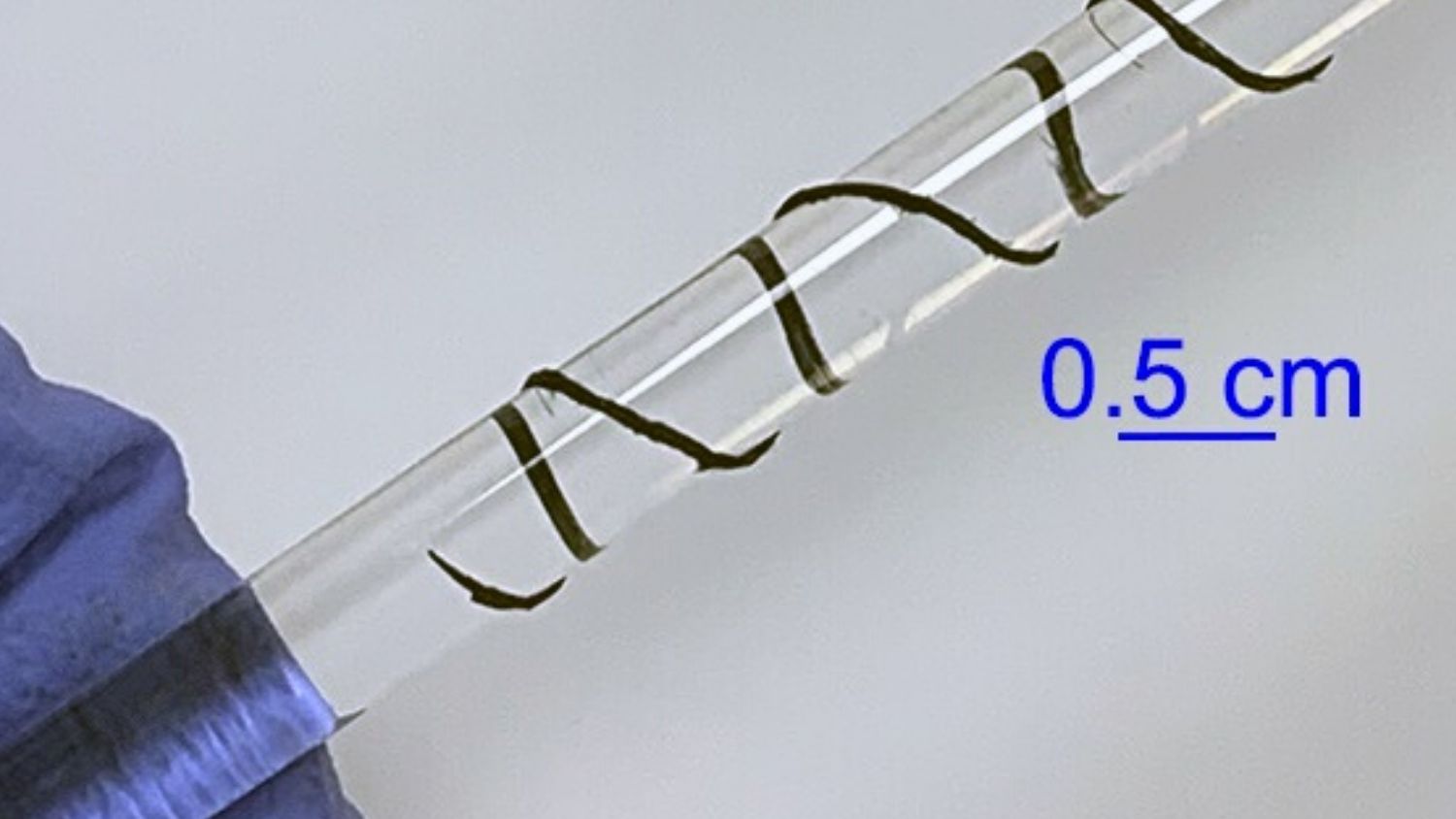

・ アイオワ州立大学が、フレキシブルなポリマーフィルムにエアロゾルジェットプリンターで作製したグラフェン・バイオセンサーを開発。安価で大量生産へのスケールアップが可能なバイオセンサープラットフォームを提供する。

・ 同バイオセンサーは、米国食品医薬品局(FDA)が設定するヒスタミン濃度基準値の 50ppm よりさらに低濃度の3.41ppm を検出できる。ヒスタミンは魚や肉の腐敗を示し、アレルギー症状を起こす原因となる。

・ 同センサーでは、グラフェンに化学的に結合させたヒスタミン抗体が、ヒスタミン分子に選択的に結合し、それによる電子移動の阻害で起こる電気抵抗の変化を測定・記録する。

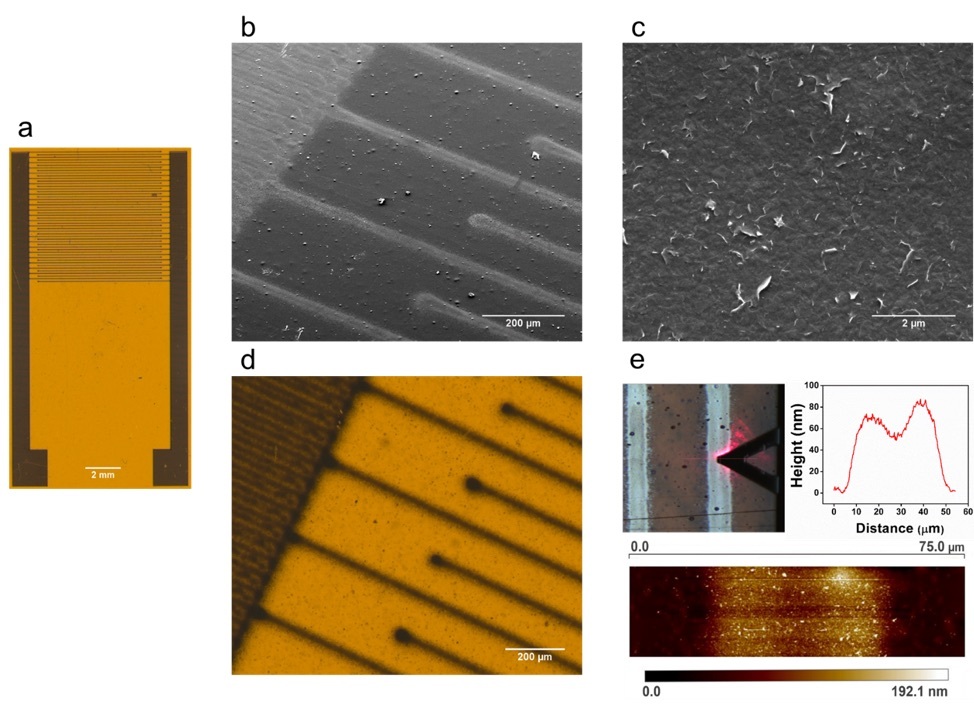

・ ヒスタミンのような小分子検出の電気化学センサーに必要な精度を提供する、低コストのエアロゾル・インクジェット技術で作製した高解像度のグラフェン電極が同センサーの鍵。より高密度に電極指をプリント作製することで、バイオセンサー感度が向上する。

・ 同バイオセンサーのエアロゾル・ジェットプリンティングと機能化のプロセスは、ヒスタミン以外の分子検出への応用も可能。例えば、センサーに結合させる抗体を変えることで、サルモネラ菌やガン、鳥インフルエンザのような家畜病の検出にも対応。環境毒素や食物媒介性の病原菌の検出や、ウェアラブルな健康モニタリング・診断等、様々なアプリケーションが考えられる。

・ 同バイオセンサーを調整し、炎症のマーカーであるサイトカインの検出を実証。蓄牛の免疫システム機能のモニタリングや、伝染性の致死的なパラ結核病の初期段階での検出も可能。

・ 同大学の Research Park を拠点とするスタートアップの NanoSpy.Inc.が、ヒスタミンとサイトカイン検出の同バイオセンサー技術のライセンス供与の手続きを実施中。

・ 本研究は、米国立科学財団(NSF)、米国農務省(USDA)、米空軍研究所(AFRL)および米国立標準技術研究所(NIST)が支援した。

URL: https://www.news.iastate.edu/news/2020/06/25/graphenesensors

<NEDO海外技術情報より>

(関連情報)

2D Materials 掲載論文(アブストラクトのみ:全文は有料)

Aerosol-jet-printed graphene electrochemical histamine sensors for food safety monitoring

URL: https://iopscience.iop.org/article/10.1088/2053-1583/ab8919

Applied Materials & Interfaces 掲載論文(アブストラクトのみ:全文は有料)

Aerosol-Jet-Printed Graphene Immunosensor for Label-Free Cytokine Monitoring in Serum

URL: https://pubs.acs.org/doi/10.1021/acsami.9b22183

Abstract

Carbon nanomaterials such as graphene exhibit unique material properties including high electrical conductivity, surface area, and biocompatibility that have the potential to significantly improve the performance of electrochemical sensors. Since in-field electrochemical sensors are typically disposable, they require materials that are amenable to low-cost, high-throughput, and scalable manufacturing. Conventional graphene devices based on low-yield chemical vapor deposition techniques are too expensive for such applications, while low-cost alternatives such as screen and inkjet printing do not possess sufficient control over electrode geometry to achieve favorable electrochemical sensor performance. In this work, aerosol jet printing (AJP) is used to create high-resolution (~40 μm line width) interdigitated electrodes (IDEs) on flexible substrates, which are then converted into histamine sensors by covalently linking monoclonal antibodies to oxygen moieties created on the graphene surface through a CO2 thermal annealing process. The resulting electrochemical sensors exhibit a wide histamine sensing range of 6.25–200 ppm (56.25 μM–1.8 mM) and a low detection limit of 3.41 ppm (30.7 μM) within actual tuna broth samples. These sensor metrics are significant since histamine levels over 50 ppm in fish induce adverse health effects including severe allergic reactions (e.g. Scombroid food poisoning). Beyond the histamine case study presented here, the AJP and functionalization process can likely be generalized to a diverse range of sensing applications including environmental toxin detection, foodborne pathogen detection, wearable health monitoring, and health diagnostics.